The maintenance of sawmills can be organised in many different ways. The size of the sawmill and volume of production are factors that affect the way maintenance is organised. There are many alternative solutions and no one solution fits all settings.

Models for organising maintenance

- The sawmill can have its own maintenance services or they can be acquired from a service provider or providers as a subcontracting service.

- Maintenance can focus solely on running the sawmill processes while additional services are acquired from outside subcontractors.

- Responsibilities related to different technical areas can be shared between production, maintenance and the service providers so that the overall maintenance consists of a combination of different models.

Buying maintenance services

Sawmills aim to focus on their production and, today, some of their maintenance services are often acquired from specialist companies.

Buying maintenance services can be divided into three main general groups:

- Acquiring a single service or product

- Acquiring a service plan related to an individual piece of equipment or section of the process

- Acquiring an entire maintenance service package from a service provider

Procurement and materials related to sawmill maintenance

The material storage at a sawmill can include up to 1,000–7,000 different items. When the number of maintenance material suppliers is high and the technical age structure of the different sections of the sawmill’s process varies greatly, the number of items to be stored increases.

Storage record keeping software should allow separate maintenance tasks or maximum storage times to be entered for all stored components and equipment in order to ensure that they remain in good condition even after a long period of storage.

The following tasks are included in maintenance material logistics and storage management:

- Predicting the need for materials

- Receiving, checking and shelving deliveries

- Collecting materials and packaging where necessary

- Supplying storage items to their correct locations in the extent and at the time agreed

- Sending items that leave through the storage outside the sawmill

- Entering incoming and outgoing items into the system

- Maintaining the storage in good order

- Inventories and reporting

- Maintaining a list of the names of parts and components used for different machines and equipment

- Agreed item call-outs determined individually

- Suggestions on the maintenance of storage machinery and equipment

- Maintenance tasks, such as maintaining a supplier register and database and updating price lists and sales and purchase price lists related to the maintenance system

- Scrapping

Distribution of service and material costs. The graph shows the share of material costs out of the overall maintenance costs. © Caverion Suomi Oy

Management of material logistics is very important because, if a delivery is faulty or an urgent delivery is late, it will have a direct impact on the schedule of any fitting and servicing tasks or the tasks might not be performed at all.

Maintenance system

Maintenance produces high volumes of documented information and, when members of staff move on into other roles, the relevant know-how may be lost. By using the maintenance and documentation system correctly, unexpected situations like this can be prevented.

The maintenance system must support the daily operations of the maintenance department and assist the overall work of maintenance and production.

Maintenance systems include sections related to

- material acquisition

- equipment hierarchy

- fault messages

- commissions

- procurement

- documentation

- the supplier database and working time

- project management

Carrying out maintenance services

No sawmill carries out all of its maintenance work alone nor do outside maintenance service providers produce all services themselves.

The different operators all take part in the maintenance of the sawmill. The production staff monitors the condition of the machinery in their work while the different machinery suppliers provide specialist services related to their own machines.

The authorities also demand that certain legal requirements concerning maintenance are met.

The role of preventative maintenance at sawmills cannot be highlighted enough. It is vital to prepare for the annual maintenance stoppage and perform it correctly.

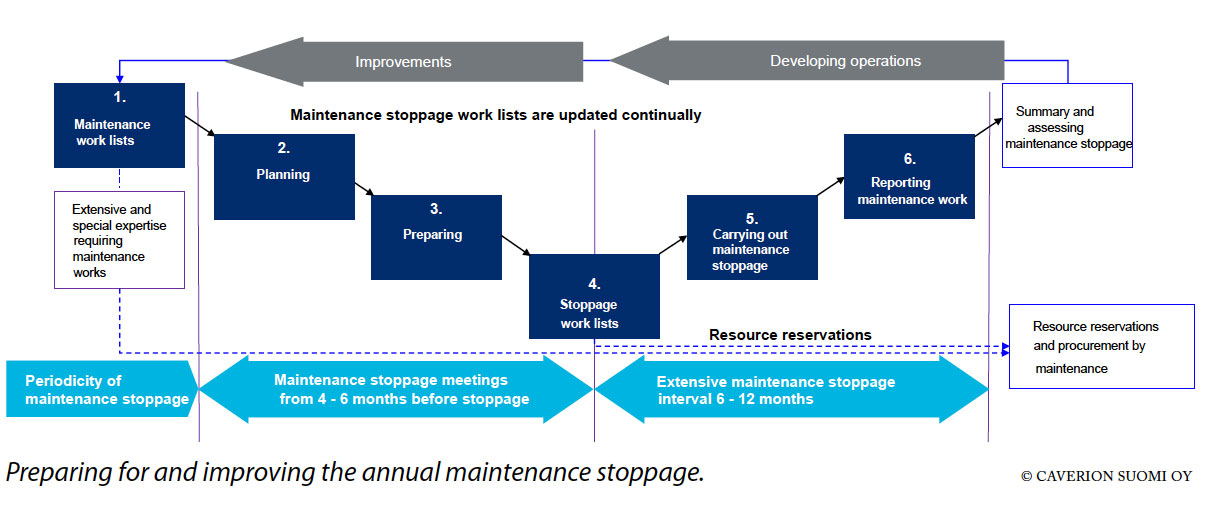

The picture shows a sawmill maintenance stoppage outline and the steps that are included in preparing and performing annual maintenance and how it can be improved.

© Caverion Suomi Oy.

Long and extensive maintenance tasks should be performed during the annual maintenance stoppage.

Shorter tasks can be done during department-specific and weekly maintenance, and the sawmill’s own staff should be used as much as possible.

From the point of view of costs, department-specific and weekly maintenance should only be performed by outside operators if the tasks require specialist skills.