Structural timber refers to spruce or pine timber that is used for load-bearing structures or part of such a structure and for which there are set minimum strength and elasticity requirements.

Principle

Structural timber is graded either visually or by machine. Visual grading requires sufficient expertise from the person carrying out the grading. Usually, this means training in grading course and passing examination.

Machine strength grading is based on mechanical measurements of the timber’s density and knots

The qualifications of graders and conformity of the grading process is supervised by a Notified Body (such as Finotrol Oy, Inspecta Sertifiointi Oy or Eurofins Expert Services Oy in Finland) that can issue a certification for the sawmill’s quality control that gives the sawmill the right to use CE marking.

CE-marking

All machine graded timber must have the CE marking. Moreover, the manufacturer is responsible for presenting the Declaration of Performance (DoP) that provides details on the product’s properties.

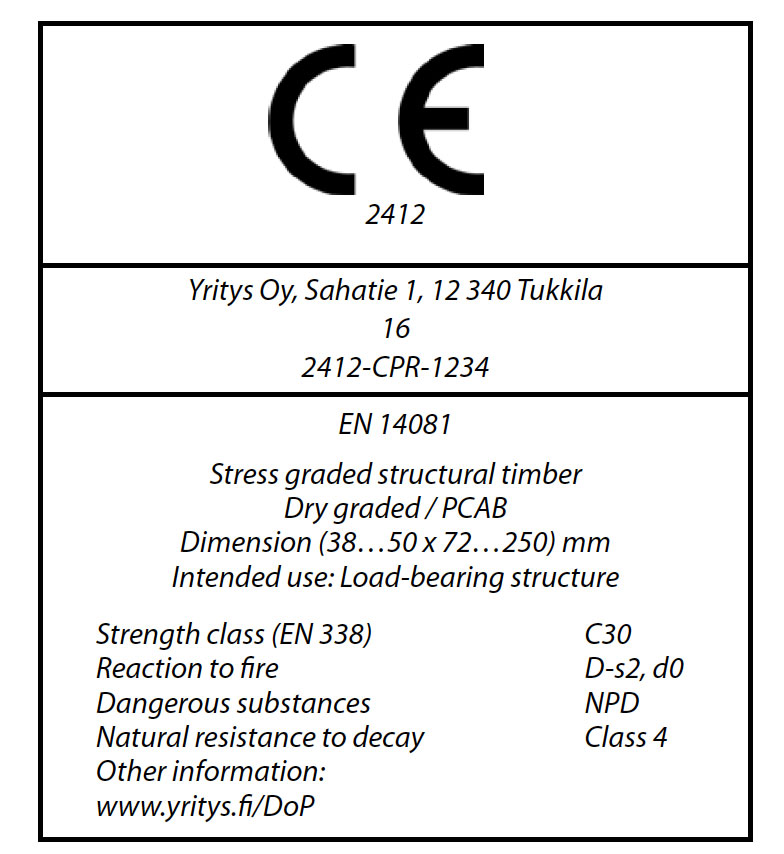

Two examples (stamp and text) of the CE marking on an individual piece of machine strength graded structural timber.

An example of a CE marking on a package of visually strength graded timber.

- 2412 = identifier of the Notified Body

- CPR = construction products regulation

- 1234 = certificate number

- M = machine grading

- C30 = strength class

- 16 = last two figures of the year in which the marking was applied

- PCAB = species: spruce

Features compromising the strength

Visual grading is based on the detection by human eye or artificial vision of defects that may compromise the strength of the timber. These defects include:

Knots are not categorised based on their characteristics. They may be sound, rotten, bark-ringed or even a knot hole. The location, size and numer, are decisive factors when deciding to which strength class a piece of sawn timber belongs.

Grain defects. A typical damage causing grain defects is top break. This can be detected easily on the inner face of the piece when 2-exlog sawn.

Rot is caused by white-rot or brown-rot fungi. They break down the wood’s lignin (i.e. bonding agent) and cellulose. A 5% weight loss caused by the fungi weakens the strength by nearly 50%.

Fissures are assessed based on their length, depth and location. Type of fissures described in chapter 6.1 include drying checks, felling shakes and ring shakes.

Compression wood causes deformation as it dries.

Deformations include a bow, spring, twist and cup. These deformations affect the usability of the timber.

Wanes reduce the nominal cross-section area of timber and weaken its strength as a result.

Bark and insect marks. Almost no bark at all is allowed on strength graded timber. Bark is the perfect environment for insects that can cause damage to the wood. Insect defects are mostly aesthetic but can weaken the timber if their number is very high. Bark pockets are assessed based on their length and width.

Mechanical defects are mainly damage caused by an external impact (forklift, chain conveyors, etc.) during handling.

Blue stain, discolouring, resin pockets, resinious wood and weathering do not affect the strength of the timber nor is it necessary to lower the strength grade on their account. However, they are often such visible defects that they are undesirable on the final product and so the timber ends up being rejected.

Grading rules

INSTA 142 -standard

The most commonly used official grading standard in Finland is the INSTA 142. It is a Nordic standard that is an approved national standard in Denmark, Finland, Norway, Iceland and Sweden. It is in line with the grading requirements of standards EN 1912 and EN 14081-1.

INSTA 142 calls graded timber T-timber or LT-timber if it is for glued laminated constructions. According to the standard, the main species used as structural timber in Finland are spruce (Picea abies) and pine (Pinus sylvestris) that have grown in Northern and North Eastern Europe i.e. in the NNE Europe growth area.

Grades

This standard identifies the characteristic values and defines the quality requirements for visual strength grading of timber. Within the INSTA 142 grading, the grades are organised in descending order: T3 – T2 – T1 – T0.

The values correspond with the characteristic bending strength values of 30N/mm2, 24N/mm2, 18N/mm2 and 14N/mm2 as well as the standard EN 338 strength values of C30, C24, C18 and C14.

The strength grade number (C-value) refers to the required breaking strength of a piece of timber in this strength grade when being subjected to stress for approximately five minutes while having a moisture content of 12%. For example, the breaking strength of C30 (T3) under the conditions described above must be at least 30N/mm2.

Timber that is split after grading must be re-graded either visually or mechanically. In visual grading only classes T2 (C24) and T1 (C18) are exixting.

Glulam grading uses the strength grades LT40, LT30, LT20 and LT10. In practice, the grading classes LT30 and LT20 are used that correspond with the gluelam grades T22 and T14 of EN 14080:2013. The rules can be applied to both pressure impregnated or unimpregnated timber.

When grading timber into grades higher than C30, only machine grading is acceptable.

The majority of timber is machine graded using grading methods that are based on measuring characteristic frequency, X-ray or ultrasound measuring and bending the piece of timber.

The most commonly used of these methods in the Nordic countries is measuring characteristic frequency that is many times faster than, e.g. the grader based on bending of piece. Standard EN 14081-1 gives instructions to the grader on removing any timber with visible defects from among the machine graded timber.

BS-standard ja DIN-norm

Other standards used in visual grading in Finland include the British BS standards and German DIN rules. The BS EN 4978 standard for timber mainly intended for the UK market uses two strength grades: C24 (SS = Special Structural Grade) and C16 (GS = General Structural Grade). DIN 4074-1 uses grades C16 (S7), C24 (S10) and C30 (S13).

Grading rules

Heartwood and sapwood are equally valuable in grading. Grading is nearly always done on dry timber with a moisture content of 18% (+2% / -2.5%).

The timber target size refers to the size with a moisture content of 20%. Strength graded timber can be planed without lowering the grade when the edge or face being planed is reduced by no more than 5mm when the original thickness is ≤100mm or by no more than 10mm when the original thickness is >100mm.

The grading rules are divided into three groups:

- Full timber with a thickness of ≥45mm and width of ≥70mm

- Split timber that is smaller than the above (up to 25mm x 50mm)

- Timber used for glued laminated (gluelam) constructions.

INSTA 142 summary of strength grading rules for unsplit timber.

INSTA 142 summary of strength grading rules for split timber