Knots

The location, number, size and type of knots are the decisive factors when deciding to which grade the a piece of sawn timber belongs.

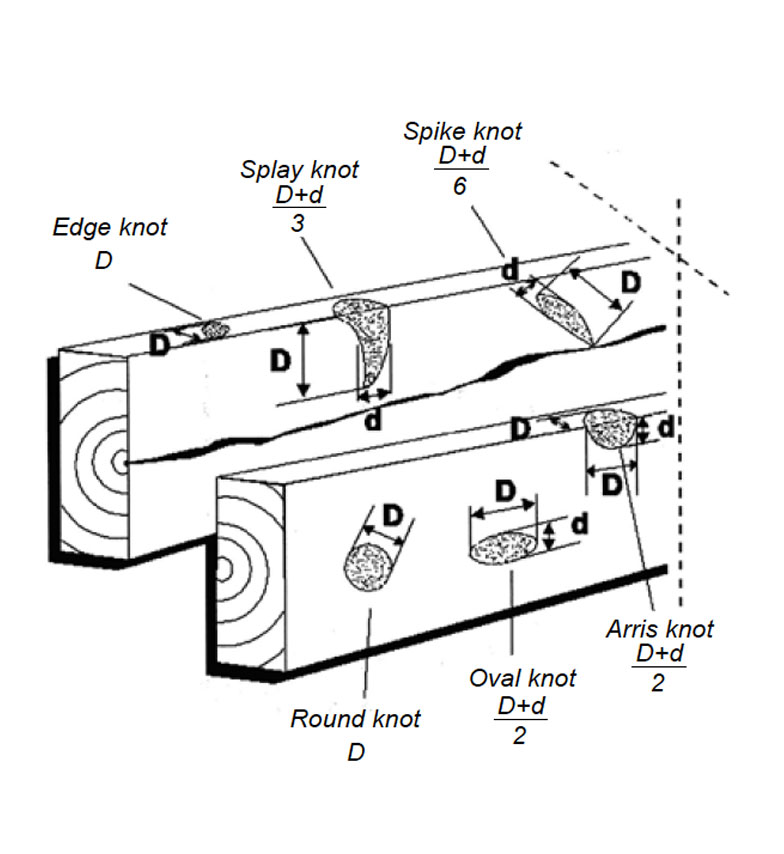

Form of the knot

- Round and oval knots are sawn more or less straight across and are located on the faces or the edges of a piece.

- Arris knot. A knot located in the intersection of a face and an edge of a piece.

- A splay knot is a knot on the inside face of the piece, which extends to the arris and which partly shows also on the edge. Top rupture occurred in growing trees can create vertical or cone shaped knots. These are classified as splay knots.

- A spike knot is a split knot on the inside face, which does not extend to the arris of the piece.

The knots are divided according to their location into face knots, edge knots and arris knots.

Internal position of the knots

- Scattered knots are knots which are spread along the piece and do not form knot clusters.

- Knot cluster is a group of adjacent knots which have clearly separated grain deviations. If the knots are not clearly separated by undisturbed grain, they are considered as one knot. Knot clusters are evaluated on the outside face as well as on the edges. In order to be considered a knot cluster, it must contain at least 4 knots with a diameter bigger than 12mm and the whole group of knots must be located within 150mm of the length of the piece.

Different types of knots

- A sound knot is intergrown to more than with the surrounding wood.

- A dead knot is a knot whose function in the growing tree has ceased. A dead knot can be black or loose.

– A black knot is a dark coloured dead knot.

– A pin knot is a very small dead knot, usually dark coloured, with a diameter of not more than 7mm. - A barkringed knot is partly or completely surrounded by bark. If less than . is encircled by bark, it is evaluated and classified as a dead knot.

- An unsound knot is completely or partly damaged by rot.

Size and measuring

Face knot (round and oval knots). The size is the mean value of the biggest diameter D and the smallest diameter d.

Splay knot. The part visible on the inside face is measured as the sum of the length and the width of the knot divided by 3 (the width is measured in the middle). The part of the knot visible on the edge is measured according to the rule for edge knots.

Spike knot. A spike knot on the inside face ceases before the arris. It is measured as the sum of the length and width of the knot divided by 6 (the width measured in the middle).

Edge knots are measured perpendicular to the length of the piece.

Arris knot. The part of the knot visible on the face is measured according to the rule for face knots. The part of the knot visible on the edge is measured according to the rule for edge knots.

Guidelines for measuring the knot size

Fissures

Drying checks

These fissures occur in the sawn timber in connection with seasoning. The drying checks can be parallel or diagonal to the length of the piece depending on the grain direction within the piece. The depth and the width of the drying check is usually dependent on the length of the check.

Heart shakes

These are shakes that run along the radii from the pith in the middle of the tree towards the surface. They are formed in the heartwood due to internal stresses within the tree.

Ring shakes

These are shakes that are running along the annual rings, concentric with each other. They can sometimes be distinguished on the end surface of newly cut timber.

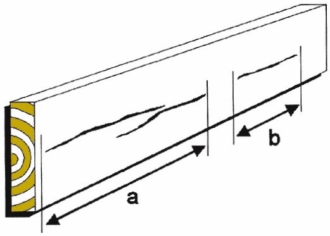

Measuring the fissure length

The fissure length, S, is given as percentage of the timber lengt where (a+b) = the total length of the fissures in the piece, see figure above.

Parallel drying checks run in one direction, parallel to one another, through their whole length. Drying checks can be oblique and they can also go through the arris. When evalauating the fissure length, they are considered as one single fissure.

Other features

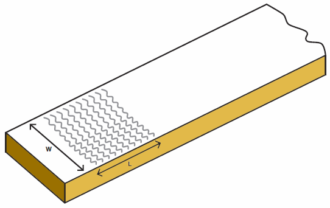

Wane

Wane is the part of the surface of sawn timber, which has not been touched by the saw. The length and the depth of wane are given as a percentage of the nominal size of the sawn timber piece. The width is given in mm.

Resin pockets

A resin pocket is an opening between the annual rings of the sawn timber piece. It is usually filled with resin. The opening is occluded the same year it is formed. Its size is measured as mm along the length of the piece.

Bark pockets

A bark pocket is intergrown bark. The bark pocket can be formed e.g. by overlaying growth of a butt scar. This is measured the same way as the resin pocket.

Scars

A scar is an opening caused by damage to growing tree, which has been healed over in trunk by occlusion. The fibres of the occlusion are often irregular and mostly resinous. This is measured by the same way as the resin pocket.

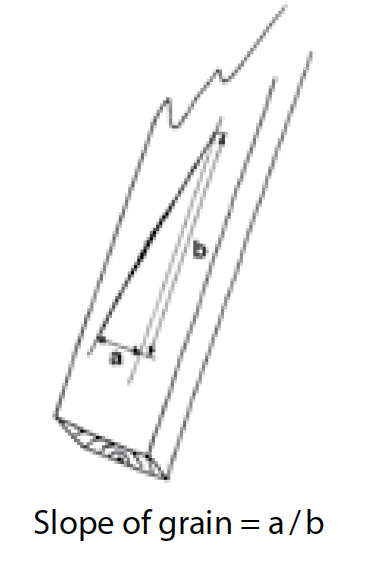

Slope of grain

Slope of grain means that the wood fibres do not run parallel to the piece. The deviation of the grain direction from the longitudinal direction of the piece measured on the outside face is the value for slope of grain.

Top rupture

Top rupture is formed when the tree is broken and the growth tries to repair the damage. The grain deviation is usually followed by formation of compression wood and curly grain with lower strength properties as a result.

If it has the character of a vertical knot, it is evaluated and classified as a splay knot. If the damage is visible as a grain deviation, it is evaluated as a percentage of the timber width and classified as top rupture.

Mikäli viasta aiheutuu pysty- tai poikaoksa, mitataan ja luokitellaan se kuten sarvioksa. Jos vaurio näkyy syyhäiriöinä, määritellään se prosentteina kappaleen leveydestä ja luokitellaan latvamurtumana.

The size of top rupture is in proportion to the diameter of the trunk at the time of the damage.

Compression wood

Compression wood is wood with abnormal fibre properties. It has been formed to compensate for abnormal compression stresses within the tree. The wood material is harder and often darker than the surrounding normal wood material.

Compression wood is measured by the % of the surface of the total piece. Area X compression percentage (length x width x compression persentage).

Curly grain

This kind of wood has very irregular grain, which runs in different directions. Curly grain is formed e.g. due to local disturbances of the growth. The area containing curly grain is given as a percentage of the surface of the piece and is measured according to the guidelines for compression wood.

Resin wood

Resin wood is wood containing an abnormal content of resin. The amount of resin wood is given as a percentage of the area of the piece.

Fungus infections

Different kind of funghi e.g. mould, stain and rot producing fungi, can infect the wood and cause light to strong discolouration. The infection can be superficial or penetrate deep into the sapwood.

Log blue stain

This blue stain usually penetrates deep into the wood or through the piece and it already exists in the log prior to sawing. The amount of log stain is given as a percentage of the area of the piece.

Rot

Rot is formed when the wood is infected by funghi producing rot. Two types of rot are distinguished. Hard rot means that the wood has not lost its firmness. Soft rot means that the wood is not firm anymore and yields when pressed. The amount of rot is given as a percentage of the area.

Warp

Bow

The faces are bowed in the longitudinal direction of the piece. Bow is measured as the height of the bow in mm within 2m of the piece.

.

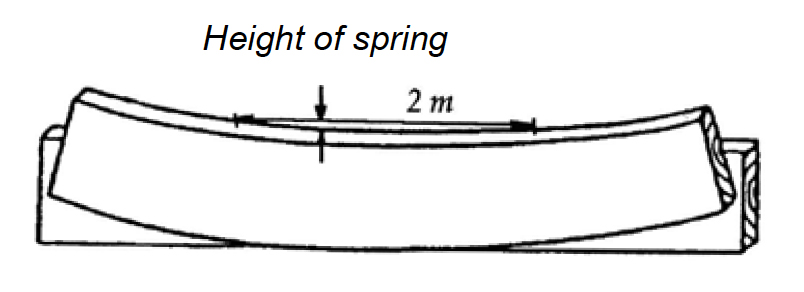

Spring

The edges are bowed in the longitudinal direction of the piece. Spring is measured as the height of the spring in mm within 2m of the piece.

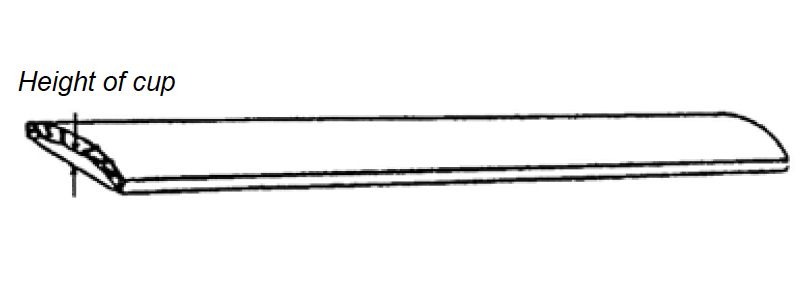

Cup

This is how concave or convex a piece of sawn timber is cross directionally. It is measured as the height of cup across the width on the concave face and evaluated as a percentage of the timber width.

.

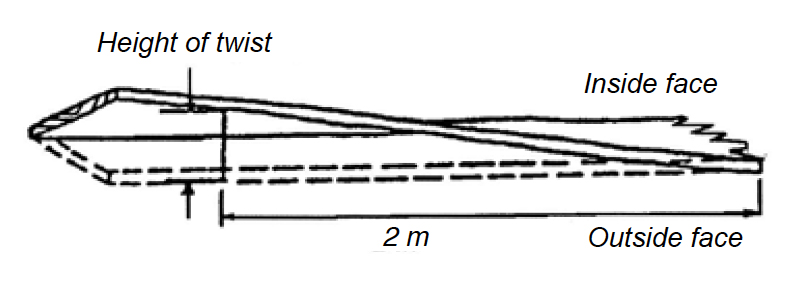

Twist

Twist is a flatways in the form of a screw. It is measured as the height of deviation within 2 m of the piece from the level plane to the outside face of the piece and evaluated as a percentage of the timber width.

Other definitions

Moisture content

Moisture content is the weight of the water in the wood compared to the weight of absolutely dry wood. Moisture content is given as a percentage.

Width of annual rings

The width of annual rings means average width. The annual rings located more than 25mm from the visible or imaginary pith are measured. For practical reasons the width of annual rings is usually measured in the butt end. Width of annual rings is given in mm.

Size deviation

Size deviation is the amount of deviation from the nominal size, which is greater than the permitted deviation.

Shinkage of knots

This occurs when a loose dead knot shrinks from the plane of the surface of the piece during seasoning. The knot adheres to the wood at the end of seasoning and forms a bump on the other side of the piece. Shrinkage of knots is not considered if it stays within the permitted size deviations of the piece

Discolouration

Such superficial colouring as bark brown, weathering and mould is called discolouration. They may develop during seasoning and storage.

Handling damage

This is damage occurring during the handling of the goods, e.g. damage caused by infeed rollers, cutting tools or drops. These damages in depth, if measurable, are classified like barkringed knots.

Water storage damage

This kind of damage may occur after storage in water for a long period or lengthy watering of logs stored on land. Such damage cannot be evaluated in normal grading.

Insect damage

Insect damage can be divided into wood wasp attack (e.g. hymenoptera, ants, bees, wasps) and insect holes (bark beetles). Insect holes are normally less than 2mm in diameter.