Harvester’s cross cutting volumes and quality are steered by devices installed in the harvester itself. The first step of adding value to the log takes place in the forest, where the trees are cross cut from the quality, length and top diameter point of view in the best possible way in order to meet the requirements set by the end uses.

The cross cutting is steered on the value, distribution and volumes.

The buyer, for instance, sawmill, defines the steering parameters and then passes them on wirelessly to harvester’s computer.

Parameters linked to these can be such as quality definitions or forbidden lengths or sizes.

Definitions of the yield-based and distribution-based cross cuttings

Yield-based cross cutting:

- Trees cross cutting points are defined in such a way that the volume yield results in highest possible value.

- When optimising the tree in this way one aims to find such a cross cutting proposal, which maximizes the value of the whole tree trunk.

Distribution-based cross cutting:

- Used when end-use based sawn log requirements steer the cross cutting for lengths and top diameters.

When the harvester is handling the tree trunk it chooses a cross cutting alternative, which maximizes the yield and the value of the trunk.

Cross cutting solely this way can, however, lead to an unsuitable log distribution – this is why the harvester actively steers the cutting towards desired log lengths and sizes.

Alternatively, one can choose a combination of the two cross cutting systems, where for instance the distribution based cross cutting can be only max 5% of the total. Distribution percentages are followed up harvester by harvester.

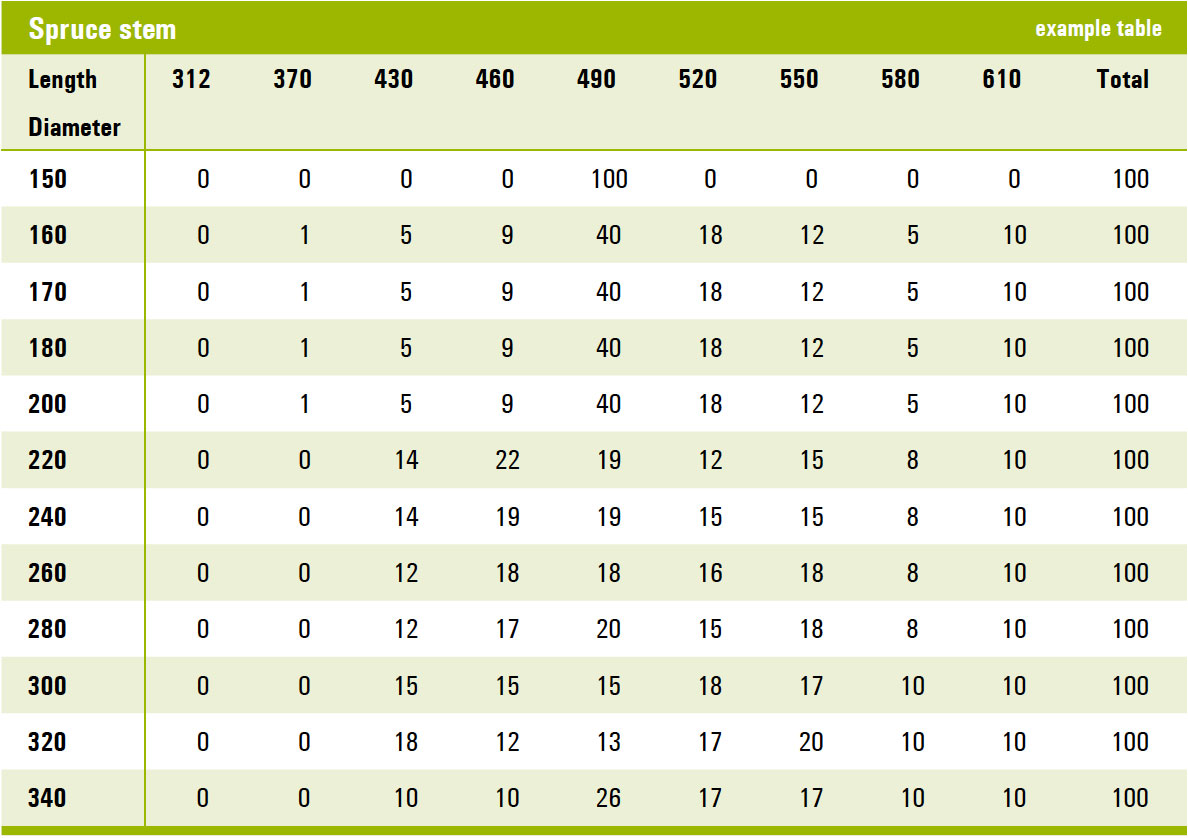

- Example of a distribution table. The cross cutting is steered by value, distribution and volumes. Parameters linked to these can be such as quality definitions or forbidden lengths or sizes.

© Metsäteho Oy

Harvester systems

In the harvester the calculations are based on the actual measurement and the prediction of the log profile made by the harvester’s computer.

In some measurements, previous data is used for the profile predictions. The accuracy of the machine and the follow up and adjustment by the harvester operator are vital for this part of the operation, too.

When sawn logs are cross cut the knots and defects determine the cross-cutting points together with the allowed log lengths.

One determines in the harvester’s computer by roundwood classes the cross-cutting parameters.

- For example, the most valuable log quality can only be cut from the butt of the tree, whereas pulp wood can be cut from other parts of the tree.

- When handling the tree the harvester operator keys into the computer the specie and starting grade or individual log’s grade.

- In qualitybased grading the operator can mark the quality parameters for the tree, for instance the dry knot line, which will then steer the cross cutting.

Success of cross cutting can be measured with the length distribution rate, which compares the targets with the actual figures.

The mills follow up the quality of roundwood and especially the length delivered. Top diameter and quality are followed up closely as well.

End marking of roundwood

It is possible to mark the ends of roundwood with different colours. This is necessary especially in cases, where there are several roundwood batches and they are to be kept separate during forest transportation and storage.

As a rule the colours are used for the more valuable sawn logs.

Currently, there is not any cost-effective way of marking and recognizing individual logs, although for instance RFID tags and different mechanical or printable identification methods have been trialled.