There are not any specified general measuring and quality rules in use, but each forest company has its own criteria for the species, measurements and qualities required.

With logging contracts the parties agree on log types, which are being felled and prepared from the forest lot in question. Wood species, composition, age and size, quality and the type of felling determine which type of logs can be felled. At the same time the length measuring principles of logs is determined.

The demand for different type of logs varies according to the market situation, but usually the sales contract covers the sales all types of wood for the felling area in question.

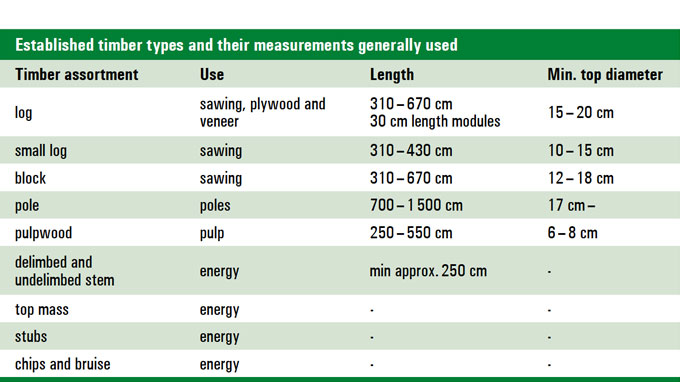

Types of timber:

- log

- small log

- block

- pole

- pulpwood

- delimbed and undelimbed stem

- top mass

- stubs

- chips and bruise

Those roundwood types, which meet the quality and measurement criteria of the industry, are called in Finnish “ainespuu”, which translates best into English as logs. Rest of the material is grouped under small logs or pulp wood.

Log types, and measuring and quality requirements

There are not any specified general measuring and quality rules in use, but each forest company has its own criteria for the species, measurements and qualities required.

These are normally factory and/or product specific and they are based on the raw material requirements.

Most common specified parameters for logs are:

- the minimum top diameter

- maximum butt diameter

- allowed lengths

- the knots, rot and other defects are taken into account

Other factors with the raw material sourcing are for instance the use of the logs (telegraph poles, wood for grinding, logs for peeling etc), first thinning material, and possible pruning of logs.

Established timber types and their measurements generally used

Pricing methods

With raw material contracts, the parties agree on the pricing principle.

Wood type based pricing

The most common one is so called wood type based pricing , because the exact value of a logging area is very difficult and expensive to assess with the trees standing.

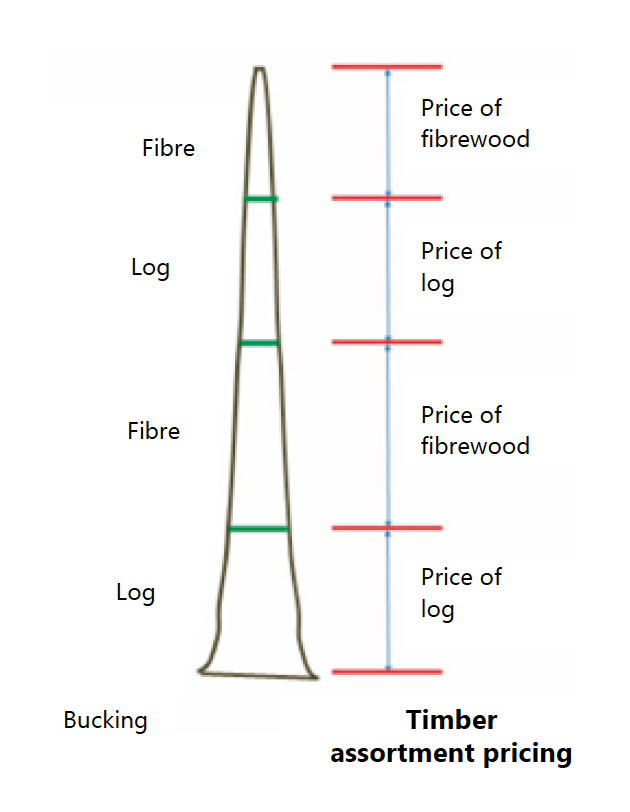

With this type of pricing the buyer and seller agree on a price to be paid for each individual wood type. With normal roundwood like sawn logs the pricing is volume based, measured on top of bark.

With energy wood there are several ways to price the material, such as the mass, energy content or volume.

In this type of pricing the key factors are the measure and quality parameters, according to which the cross cutting of logs is made. As a rule the most valuable part of the tree – the sawn logs – is maximized whenever feasible within the agreed length parameters.

Principles of wood type based pricing (timber assortment pricing). © Metsäteho Oy

These parameters are normally keyed in to the harvester’s computer, which then automatically chooses the best permutation for cross cutting. Sometimes the harvester operator may have to deviate from this, if he notices a defect in the tree trunk. With pulp wood the cross cutting is done with free lengths, allowing the top of the tree to be always cross cut to the minimum diameter.

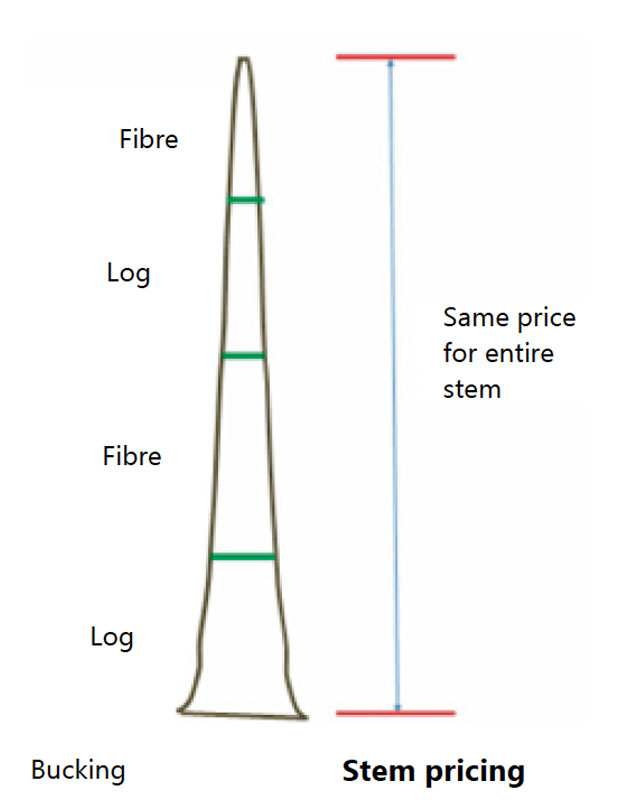

Stem pricing

Same price for entire stem. © Metsäteho Oy

When the pricing is based on the whole tree trunk, then the parties agree a price for log based on the volume of a log. Therefore, sawn log and pulp wood prices are not specified and the cross cutting can be done free of pricing related factors. The risk with this method can be that defects like rot can be ignored when the trunk is cross cut.

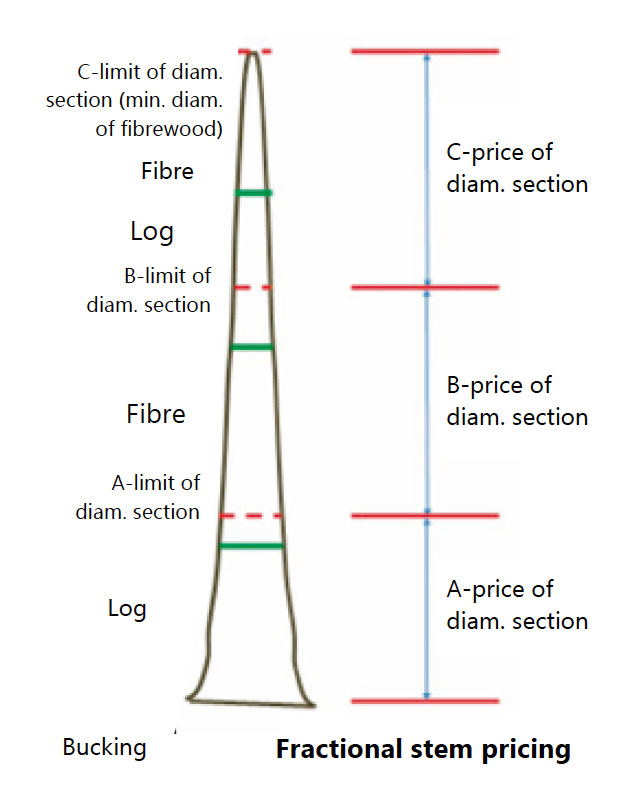

Pricing by diameter

The stem can also be priced in such a way that both parties agree for each log type certain diameter based parameters. © Metsäteho Oy

The tree trunk can also be priced in such a way that both parties agree for each log type certain diameter-based parameters. Then the price for each type of log is determined according to the volume. When processing the tree trunk details the harvester’s measuring unit determines the points, where one type of log ends and another starts – calculating at the same time the volume of each log.

Measuring methods for wood trade

With each purchase contract the measuring method is jointly agreed. For sawn and pulp wood one can use any of the wood measuring law approved method, which then gives the result in fast cubic meters over bark.

The measuring is approved, when the appropriate document is signed and forwarded to the seller. When the measuring is done either by the harvester or at the mill, the person responsible for the measuring devices and the measuring accuracy must be able to show results of their inspections.

Measuring methods are:

- Harvester measuring (by piece)

- Top measurement as fast m3 (logs)

- Measuring in piles (pulp wood)

- Measuring at the mill (several methods)

- Measuring by weight at the mill

Importance of sawn log quality

In the wood product industry value chain the cross cutting of logs is the first production related step before the actual sawing and possible further processing and end use. The properties of the end product are already found in the log, but these can be enhanced for instance with finger jointing and gluing.

From the processing point of view the most important log properties are the dimension (diameter), length and knots. Desired products can be produced only from the right sized logs which meet the quality requirements of the product.

Factors affecting the value of logs and relative values

The bigger the log the better the quality yield, thus making it more suitable to several end uses from the quality point of view. Normally the large logs are less knotty than small logs, making it usually more valuable from the further processing point of view.

Especially in pine and birch logs there is more knotless sapwood, which is appreciated in many joinery applications.

Erityisesti männyn tyvitukissa on enemmän arvokasta oksatonta pintapuuta, josta voidaan valmistaa arvokkaimmat puusepänlaatua edellyttävät tuotteet.

The volume

The volume is actually the most important factor affecting the value of the log, which is taken into account in the harvesting and cross cutting, and usually this also leads to higher prices being paid for these logs. The cross-cutting matrix is derived from end-use lengths, added with various tolerances during the sawing, kilning and grading.

Pine (Redwood) sawn logs yield roughly

- 2/3 centre cut pieces

- 1/3 sideboards

Out of the centre pieces about 10% could be classified as top joinery grades and another 30% as interior decoration related goods.

Knots

In sideboards the joinery grade is roughly the same, but the knotless yield for panels and small mouldings is smaller. In these product groups knot requirements are higher: knots are either not allowed or they need to be sound. Usually the maximum knot sizes are also clearly defined.

Strenght

In redwood about one third of the total volume is used for structural end uses and components, where certain types of knots are allowed, but the products have certain strength property requirements.

The density of wood material may also have an effect on strength properties. The strength properties of wood can also be visually assessed from the growth rings: a wide growth ring indicates fast growth which in turn points towards smaller density of the material.

Differences between spruce and pine

Lowest grades of redwood, with more and larger knots and possibly some wane, are used primarily as pressure treated materials, for structural uses in certain areas or packaging applications. Sawn goods for these types of uses and grades come mostly from the middle, dry knotted part of the tree or from small logs.

Spruce (Whitewood):

- The center cut and sideboard yields are very similar with pine

- but the resulting grades and their properties can be different

- To begin with, in whitewood there being less difference in quality properties, the size tends to be the key factor in determining the added value worth.

There is very little knotless material in whitewood, compared with redwood.

In joinery and interior decoration related uses (panels and mouldings, parquet etc) the knots usually need to be small and sound.

The knot related parameters for building components can be more relaxed.

Lowest whitewood qualities are used for building and packaging uses. Larger whitewood logs are also used for the manufacture of spruce plywood and veneers.

Relative values and yields of redwood logs vary considerably depending on the log size and the requirements of grades. If an average added value is 100, then the poorest and best added value range from 70 to 130.

In whitewood quality properties are different and there is less variation in general, therefore the added value yields do not vary as much as they do with redwood. Added value factors do, however, vary depending on the product range and from sawmill to another.

Log sorting and quality requirements

Redwood logs are generally divided into three qualities, which can even be subdivided according to special requirements.

- Knotless bottom log (so called A grade)

- Dry knotted middle or bottom log (B grade)

- Sound knotted top log (C grade)

With whitewood there are normally not any quality groupings and the cross cutting is based more on required diameter classes and lengths.

The minimum top diameter for sawn logs varies according to the market situation.

- Usually the minimum top diameter for pine is 150mm

- For spruce top diameter is 160mm over bark

- Small log and Egyptian balk log minimums vary between producers, but they are in the range of 100mm to 140mm.

Biggest allowed knot sizes are normally:

- 50 mm for a sound knot (A grade pine 20 mm),

- 40 mm for a dry/black knot

- 30mm for a rotten knot

Bow is allowed maximum 1cm per metre, but bends, rot, log blue and shakes are not acceptable in sawn logs.