Further processing at sawmills

The business logic of further processing differs significantly from basic sawmilling. The aim is to make customer’s demands and the production possibilities of the sawmill to correspond to one another.

The sawmill process can be described as one of breaking up a non-homogeneous raw material stream – sawn logs – and then combining them into homogeneous sawn goods streams for the needs of different customer segments and to large number of customers.

In this context, we are having a look only at the most important added value goods, which are integrated to sawmilling, namely planed goods and glulam. Joinery industries like windows, doors and staircases, furniture and packaging industries are not examined here. Some sawmillers are involved is house manufacturing, but that is also left out here.

Planed goods

Most important planed goods are exterior cladding, interior panelling, flooring boards, planed all round goods, regularized and strength graded goods, as well as different types of mouldings.

The biggest planing mills are nowadays either privately owned specialist mills, or independent plants in the vicinity of sawmills.

Biggest planing mills have specialised in a handful of products, where overall volumes are quite large. These companies are aiming at high market shares in chosen product groups – often including logistics and other services in the offering. Examples of these products are primed and painted, end grooved interior and exterior panel boards.

Glulam beams

Glulam beam production is usually more suited to be integrated with sawmilling than production of planed goods. Sawmills can source special length logs and produce special dimensions for the needs of the glulam beam factory in order to reduce waste.

About one third of Finnish glulam is produced by sawmilling companies and the share is increasing. One can achieve synergies in production processes, avoiding unnecessary intermediate storage, packaging and handling.

Export of processed goods

Exports of planed goods grew in the 1990s thanks to new investments. Exports did not, however, prove to be profitable in big scale, because managing the value chain all the way from Finland to the end users turned out to be challenging.

Finnish planing mill operators have concentrated on the domestic market for reasons given above. Many planing mills which operate integrated to sawmills service mainly the house manufacturing industry and the domestic merchant business for both new build and repair, maintenance and improvement. There are, however, some planing mills, which have through specialization and customer focus been able to give service to export customers as well.

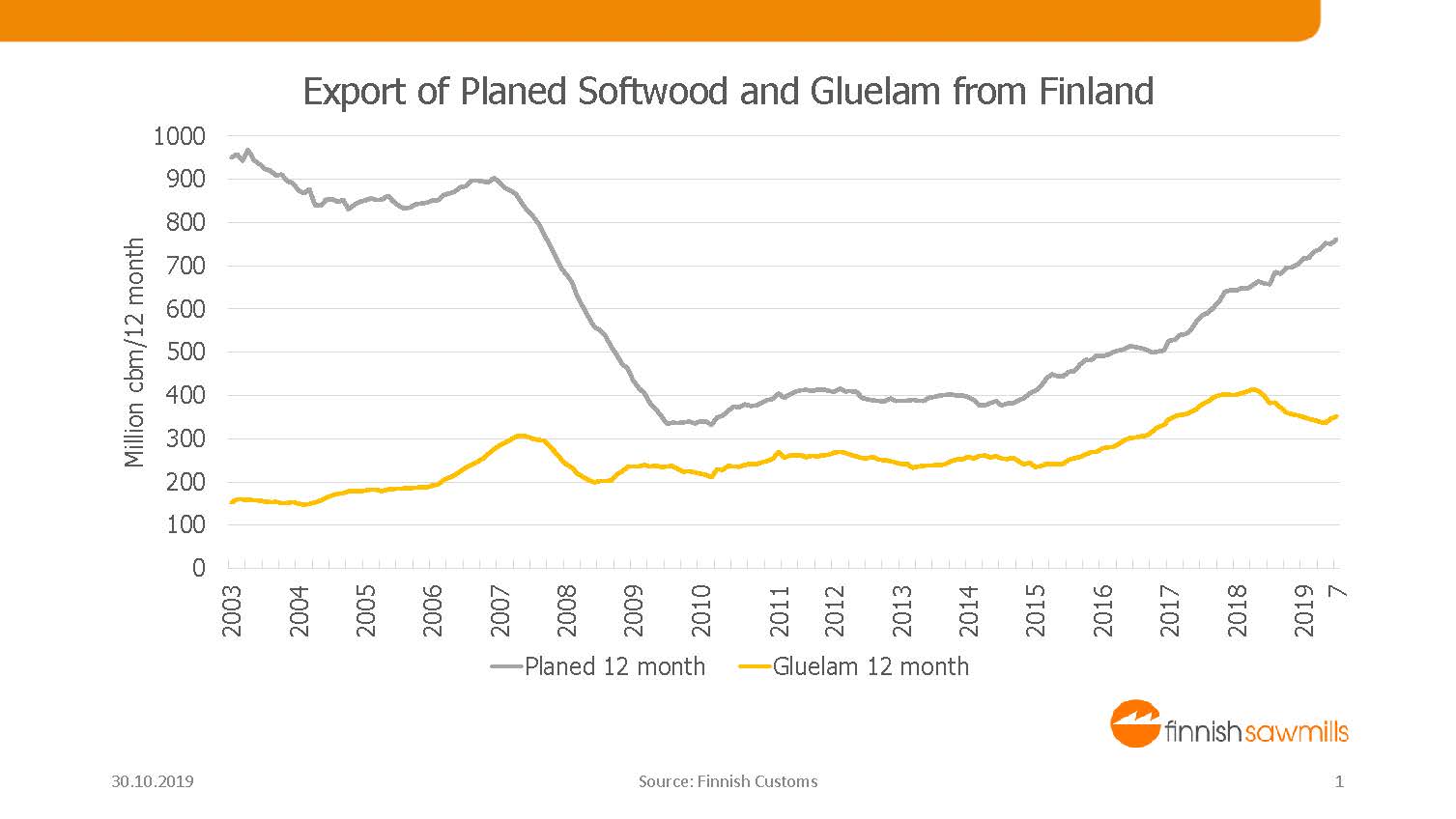

The value of exported planed goods has shrunk during the 2000s from 190 million euros to 130 million euros.

At the same time the value of exported glulam beams has risen from 50 million euros in year 2000 to over 140 million euros in 2016.

In 1990s, glulam beams were exported mainly to Central Europe. However, the Finns have not been competitive against the increased production by local producers.

Nowadays, a lion’s share of Finnish glulam beams is sold to quality conscious Japanese customers. These sales grew rapidly especially at the turn of the millennium.