Timber handling plants can be divided according to the moisture level in the sorted timber as follows:

- Green sorting (mainly based on dimension)

- Dry sorting (mainly based on quality)

- Combi sorting (combination of the two methods above)

The green sorting process handles several dimensions (thickness x width) simultaneously. In sawlines with fixed saws, the dimension of the heartwood remains the same across the entire sawing batch. However, the board width may vary.

In sawlines with changing sawing patterns, the thickness, width and number of heartwood timber and boards can vary from log to log within the batch.

In combi sorting, green and dry timber are usually processed in turns. Some combi plants can process these simultaneously if the sorting line measuring devices are able to distinguish between dry and green timber and divide them into their own bins.

Stick-stacking is also considered part of green sorting. During this stage, timber is either stacked into loads for drying, or undried timber is stacked into packages for direct sale.

Lajittelulokerot

The collection containers for the sorted timber are called bins, and they can be divided into the following types:

- cage bins (these are being phased out)

- vertical or diagonal bins

- horizontal trays

Cage bins

A cage bin is a cart with a steel frame and iron rollers. It can be moved around on tracks with side bars. The cage bins with fixed bottoms have U-shaped belts or chains that soften the impact of the first falling piece of timber. Movable bottoms are usually equipped with an electric motor. This allows for the pieces to be dropped from a lower height.

In Finland, a few sawmills still use these cage bins but they are being phased out. New cage bins are no longer being manufactured.

Vertical and diagonal bins

Vertical bins are more or less upright. The rake conveyor drops a piece of timber into a bin when the drop flap opens. If the next piece is not meant to fall into the same bin, the flap is closed. The bottom of the bin can be moved up and down by a hydraulic system or an electric motor.

There are typically 10–70 vertical bins in a dimension sorting plant. The number of bins is determined by:

- Number of goods processed in one batch,

- The frequency of batches

- The required load sizes

The properties of sawn goods in green sorting include

- Species

- Thickness

- Width

- Length

- Grade

The higher the frequency of batches, the more bins are needed.

The timber is manually or automatically emptied as a single pile from the vertical and diagonal bins on to the frequency convertercontrolled storage conveyors running under the bins.

The load is transferred to the feed conveyor where a step feeder and/or unscrambler unloads it into a carpet. The carpet can be unpacked using the stick-stacking line feeder so that there are one or two pieces between lugs, or the carpet can be transferred directly into the sticker-stacker.

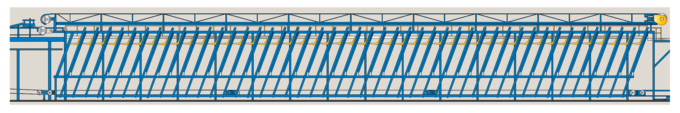

© Heinolan Sahakoneet Oy

© Heinolan Sahakoneet Oy

Horizontal trays

Horizontal trays are positioned horizontally and are 30–200 metres in length. Horizontal trays are made up of one to 25 layers, and each layer has three to five chains. The timber is collected directly from the lugs of the sorting conveyor so that they form a single carpet or float of timber.

The pieces of timber are not dropped into the trays. This way even the corners stay intact, which is important for square-edged timber. The benefits offered by horizontal trays include gentler handling of timber and prevention of mechanical damage.

At the end of the horizontal tray line is an unloading conveyor which transfers the goods from the emptied layer directly to the stickstacker.

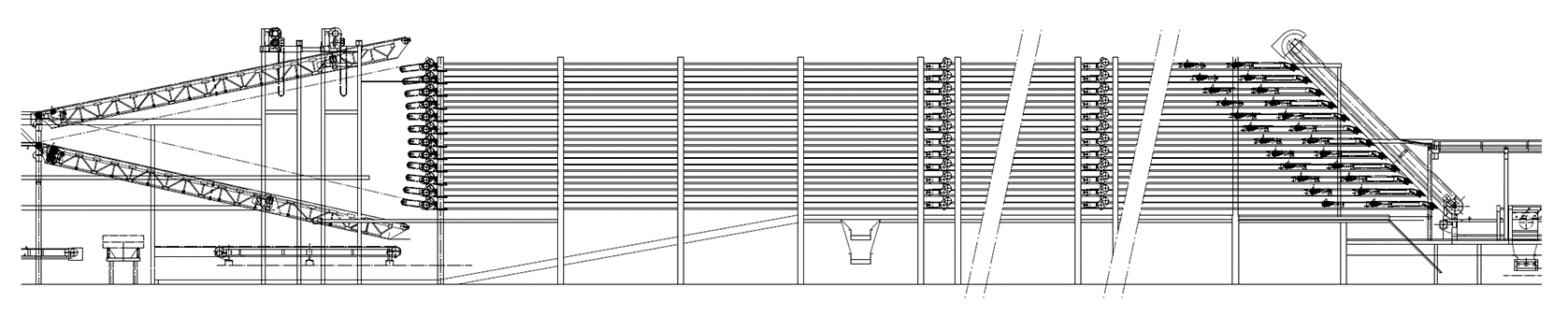

© Heinolan Sahakoneet Oy

Chains, photocells (vk) and pulse sensors ( ) of one horizontal tray, run direction ←. The conveyor divides the pieces from the lugs of the sorting conveyor to the trays. The short chains of trays 1-2 make small floats that are moved to the longer chains 3-5. © Heinolan Sahakoneet Oy

[arve url=”https://youtu.be/sAM0uiUHDV0″]