After the sorting plant timber is transferred to a buffer storage before stick-stacking.

Transferring sorted timber into buffer storage

© Heinolan Sahakoneet Oy

The timber batches are lifted out of the cage bins by a bridge crane and transferred to a buffer storage location where they await transfer to the stick-stacking line (boards) or directly to the feeder conveyor (center pieces).

The automated control system monitors the age of the batches in the buffer storage location and sends an alarm if any batches that are too old are detected. Stacked green timber is susceptible to mould in certain conditions.

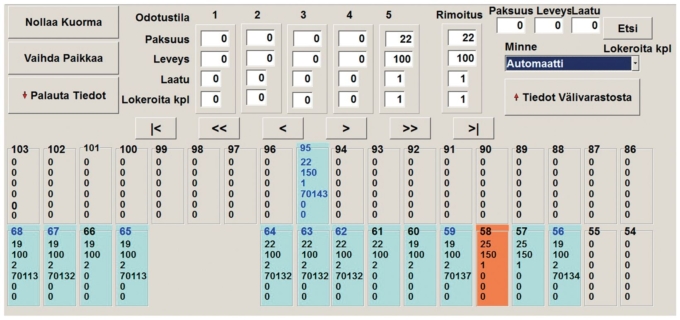

There are typically 10–30 cage bins and 100–200 buffer storages. The crane operator has a PC user interface connected to a wireless network (WLAN) which maintains and updates the cage storage. The storage data is sent live to a higher-level data system for storage record keeping.

Cage storages are being phased out because they require a lot of floor space, a bridge crane and crane operator.

Vertical bins

The vertical bin solution does not have an actual buffer storage location, unless you consider the storage conveyors (1–8 pcs) under the bins, any transverse cart or stick-stacker feeder conveyor as such. Bins that will form a single load are placed in the emptying queue in succession.

The bins in the emptying queue are emptied on to the storage conveyors, usually one bin per conveyor. The storage conveyors usually have a frequency converter control with brakes (controlled start and stop), encoder (monitored transfer distance) and photocell at the end of the conveyor (final stop).

During the sorting process, the bins are placed in the emptying queue in the order in which they become full.

By way of example, when the batch is ready, the emptying queue may be sorted in the following way (the most significant criterion is the highest and the least significant is the lowest):

- Last bin with rejected pieces: regardless of pieces

- First bin with ‘empty’ lugs: regardless of pieces

- Age of batch: the oldest first, batches not mixed

- Species: the smallest number first, species not mixed

- Moisture level: the smallest moisture rate first, different rates not mixed

- Thickness: the largest first

- Width: the largest first

- Quality: the lowest first

- Length type: 300/free + 100 + special length, different length types not mixed

- Average length: the longest first

- Fullness: the least full first, to re-circulate empty bins as quickly as possible

- The age of the oldest piece in the bin: the oldest first

The queue-emptying criteria may vary greatly between sawmills and differ from the example given above.