There are two types of timber drying kilns: chamber kilns and progressive kilns. The principle of warm air drying is to remove moisture from the wood with heat and air circulation.

Chamber kiln and air-circulation drying

Chamber kilns are suitable for the drying of all kinds of timber. The most common reasons for choosing a chamber kiln include the need to dry small batches and drying robust timber that checks easily. Typical small batches are batches that have to be dried to a low moisture content.

The transport of loads into the chamber kiln can be done either by a forklift truck, on roller tracks or E carts. Using E carts makes it possible to load the next batch when the previous one is still drying so that forklifts are not needed for changing loads at all.

© Heinolan Sahakoneet Oy

Cart and roller track solutions can also be used one after the other in so-called dual chambers that have been designed to be used as one big chamber when the material to be dried in the process schedule is the same.

The greatest benefits of chamber kilns is that batches can be dried according to their individual needs. In order to use the kiln’s drying capacity as well as possible and to maintain high drying standards, the drying process needs appropriate process schedules.

Chamber kilns should have a specific drying schedule for each species/timber thickness/final moisture content combination. Moreover, if the chambers differ slightly from one another, drying schedules should be chamber-specific.

© Heinolan Sahakoneet Oy

Drying in the chamber kilns

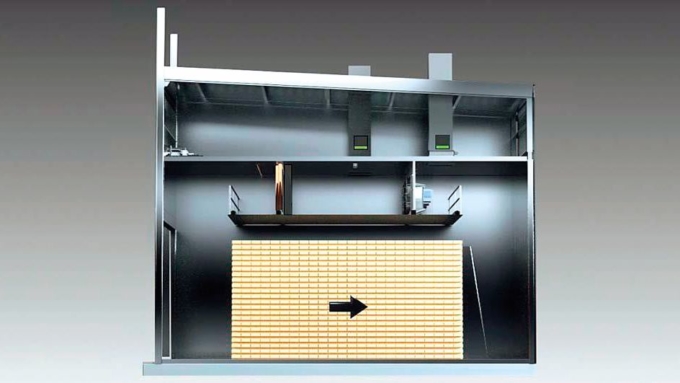

The drying process and structure of a chamber kiln in relation to the air circulation can be divided in the following manner:

- Humid air is used to transfer heat and moisture.

- Air is circulated through the stacked loads using electric motors.

- Heat is formed by radiators in order to evaporate moisture.

- Steam exits through ventilation channels.

- The kiln is loaded and unloaded using forklift trucks or carts.

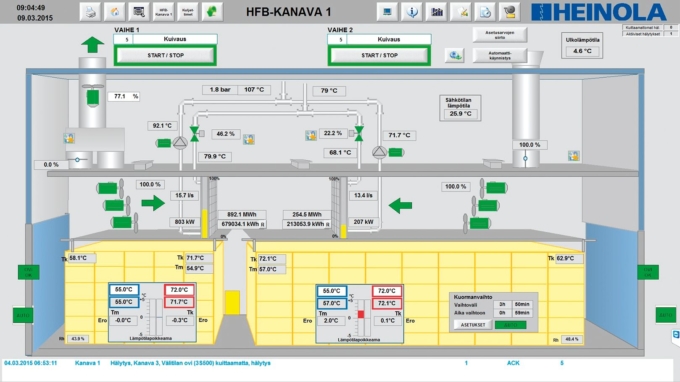

- The ambient conditions are adjusted using computer-based software mainly by measuring the dry bulb and wet bulb temperatures.

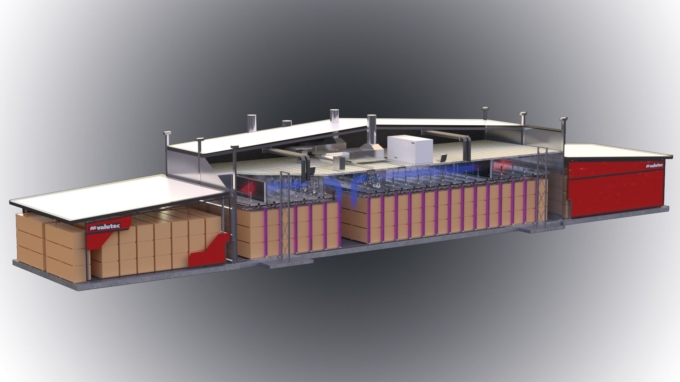

© Valutec Oy

The essential difference between chamber kiln drying and progressive kiln drying is that, in chamber kiln drying, air flows in both directions every few hours.

[arve url=”https://www.youtube.com/watch?v=1qT5xPbUn8M”]

This video highlights the principles of chamber kilning. The chamber is filled with goods from the sticker stacker machine with a forklift. Arrows depict the air direction. The progress in the kilning and the difference between dry and wet temperatures are shown on the top corner of the picture. (Duration: 1:21)

Progressive kiln and air-circulation drying

Continuous drying or progressive kiln drying is the other commonly used timber drying method.

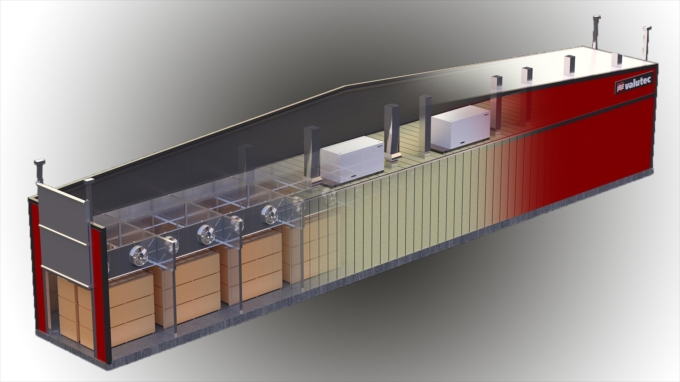

In a progressive kiln, the load travels through the kiln while the ambient conditions change as the process progresses. When drying loads are fed into the kiln, the conditions are humid in all kilns except OTC (optimised two-stage continuous) kilns.

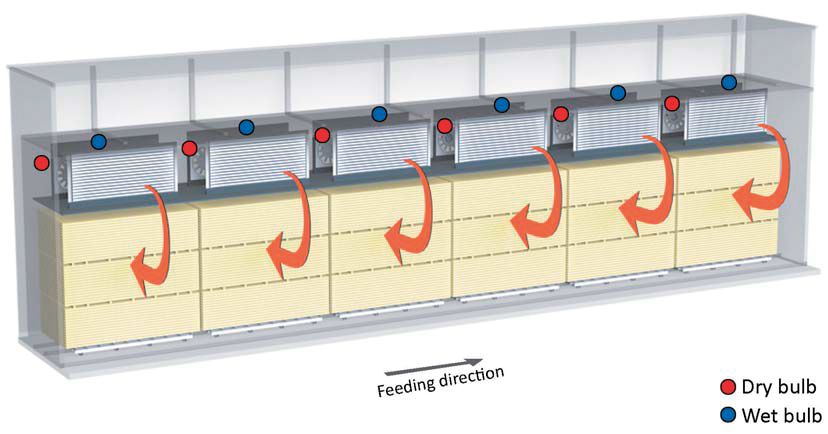

The loads travel through the kiln to the dry end following pre-calculated load exchange intervals. Heat and humidity are pushed through the dried loads using axial fans.

The basic operating principle of progressive kilns is to dry thin side boards in particular with high capacity and energy efficiency. However, technical innovations have made it possible to dry even thicker timber in progressive kilns. When this is done, the ambient conditions inside the kiln and process control are adjusted closer to those of a chamber kiln.

However, the ambient conditions inside a progressive kiln cannot be controlled as carefully as in chamber kilns because the evaporation of water from the load and the resultant conditions are dependent on the location of each load inside the progressive kiln. The drying result is affected by the exchange interval, temperature and humidity levels, the speed of air flow and the length of the kiln. The benefit of progressive kiln drying is its relatively stable demand for thermal energy and the level of venting, which results in better efficiency of the heat recovery systems than in chamber kilns.

Single-zone progressive kilns

Single-zone progressive kilns were developed to make the drying of thin side boards more profitable given the target final moisture content and moisture distribution.

The capacity of a single-zone kiln is around 35,000 cubic meters per year when the target moisture content is 15–18%..

Drying schedules are created using a combination of:

- the load exchange interval,

- ambient conditions management at the exit end,

- speed of air flow and

- the average moisture content of the timber.

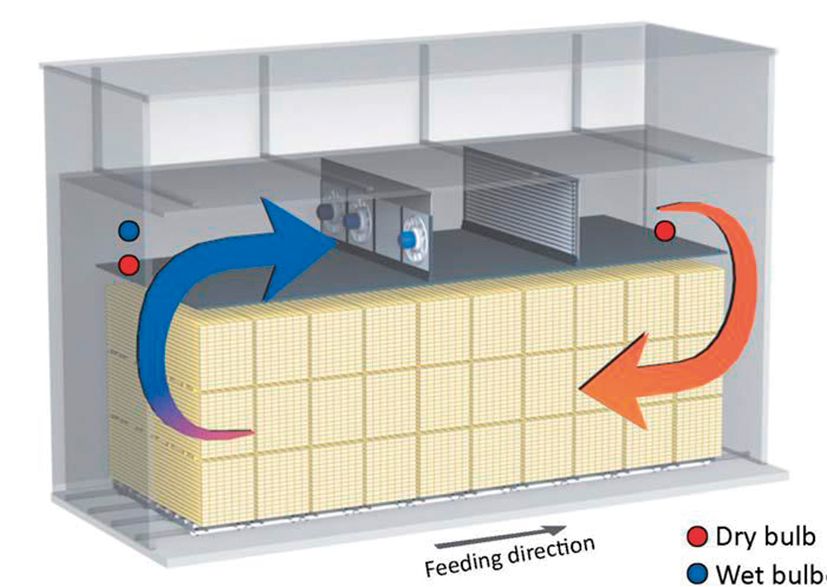

Axial fans blow circulated air through radiators into the stacked loads against their feeding direction. The air becomes more humid as the load moves towards the infeed and so the difference between the dry bulb and wet bulb temperatures becomes smaller. The length of the kiln and air-blow depth affect the temperature drop.

© Valutec Oy

© Heinolan Sahakoneet Oy

© Valutec Oy

Two-zone FB (feed back) progressive kiln

A two-zone progressive kiln offers greater capacity and more versatile functions than a single-zone progressive kiln.

The drying loads are still transferred through the kiln but the kiln has two zones.

- The first zone works like the shorter single-zone kiln quickly drying free water off the timber.

- The second zone is a slowly drying and stabilising stage that reduces the moisture level and moisture distribution as the load moves towards the exit.

This is achieved by blowing air in two different directions so that, in the first zone, the air flows against the load’s feeding direction and, in the second zone, the air flows with it.

When feeding two loads side by side, the annual capacity of a two-zone progressive kiln can be up to 90,000 cubic meters. This kiln type can also be used when the target final moisture content is low (8–10%).

© Valutec Oy

© Heinolan Sahakoneet Oy

Two-zone OTC (optimised two-stage continuous) progressive kiln

The OTC progressive kiln was designed to more closely resemble the drying schedule of chamber kilns than FB progressive kilns. This is achieved by changing the air flow directions so that, in the first zone, the air flows with the load’s feeding direction towards the infeed door while, in the second zone, the air flows against the load’s feeding direction towards the exit door.

©Valutec Oy

© Heinolan Sahakoneet Oy

© Valutec Oy

TC progressive kiln

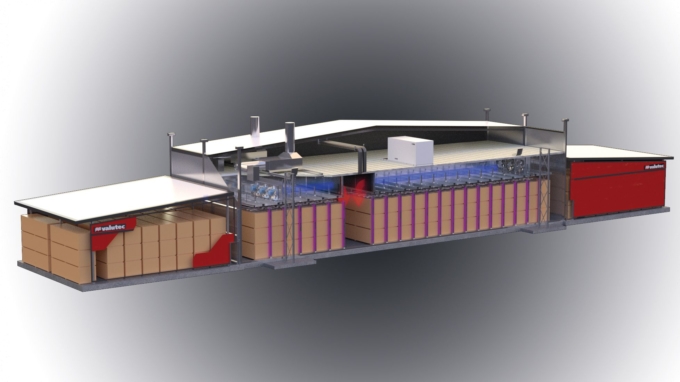

In TC progressive kilns, the loads travel through the kiln in the longitudinal direction. TC kilns, which were developed from the original transversal feeding kilns, can have 4–12 different drying stages where air is blown through the loads. Every stage has its own axial fans and radiators with which the ambient conditions of the stage are managed. Each stage can be adjusted separately, which allows for more flexibility in the planning stage.

TC progressive kilns can be used very efficiently for drying side boards. This can raise the kiln’s capacity up to 170,000 cubic meters per year when the target final moisture content is 12–18%.

© Valutec Oy

© Valutec Oy