The purpose of kiln adjustment automation is to keep the conditions of the air blown into the loads as set by the operator.

The conditions are measured using process control sensors. The set values can be entered manually so that they remain constant over time or they can be controlled by the automation system so that they can change over time.

Modern kiln automation systems consist of PC-based monitoring software, kiln-specific programmable logic controllers and the devices controlled by them.

The equipment structure of the kiln automation means that all process control happens via the programmable logic controllers and so the kiln operation is not dependent on the monitoring PC at all.

In addition to monitoring, the only measures that require the monitoring PC are changing set values and start-up for new drying batches.

All field devices, such as temperature and humidity sensors, equipment, door limits and motor control centres, are also connected to the programmable logic controllers.

The system usually comes with remote connection software for maintenance and remote support.

Principle of monitoring

In order to verify the correct operation of the kiln automation, it is important to understand that the equipment data shown on the monitoring unit’s display are mostly instructions sent to the equipment by a logic controller.

On the other hand, the absolute positioning data regarding the equipment rarely have any practical importance. When assessing the operation of the equipment, the main focus should be on the drying process itself.

In case of interruptions, the condition of motors should always be inspected in the actual equipment in question. It is possible that the regulator and the equipment using it do not operate in line with one another.

Kiln automation control loops include numerous parameters that are set at start-up and are shown on the monitoring unit’s display. These should not be changed in daily use because unplanned changes to these parameters can easily confuse the entire drying process.

Drying schedules

The temperature is adjusted using radiators and moisture using ventilation. Fan rotation speed is used to control the amount of air and the air speed through the loads throughout the process.

Drying schedules are usually fixed so that the temperature and moisture content levels are set for each drying stage, species, final moisture content, dimensions and even different times of the year.

Fixed schedules can be based on experience or simulation models. Adaptive drying schedules have been further developed and introduced at other sawmills. Adaptive drying schedules adapt to the drying process if, for example, temperatures cannot be kept at the level they were set at in the drying schedule before the process was started.

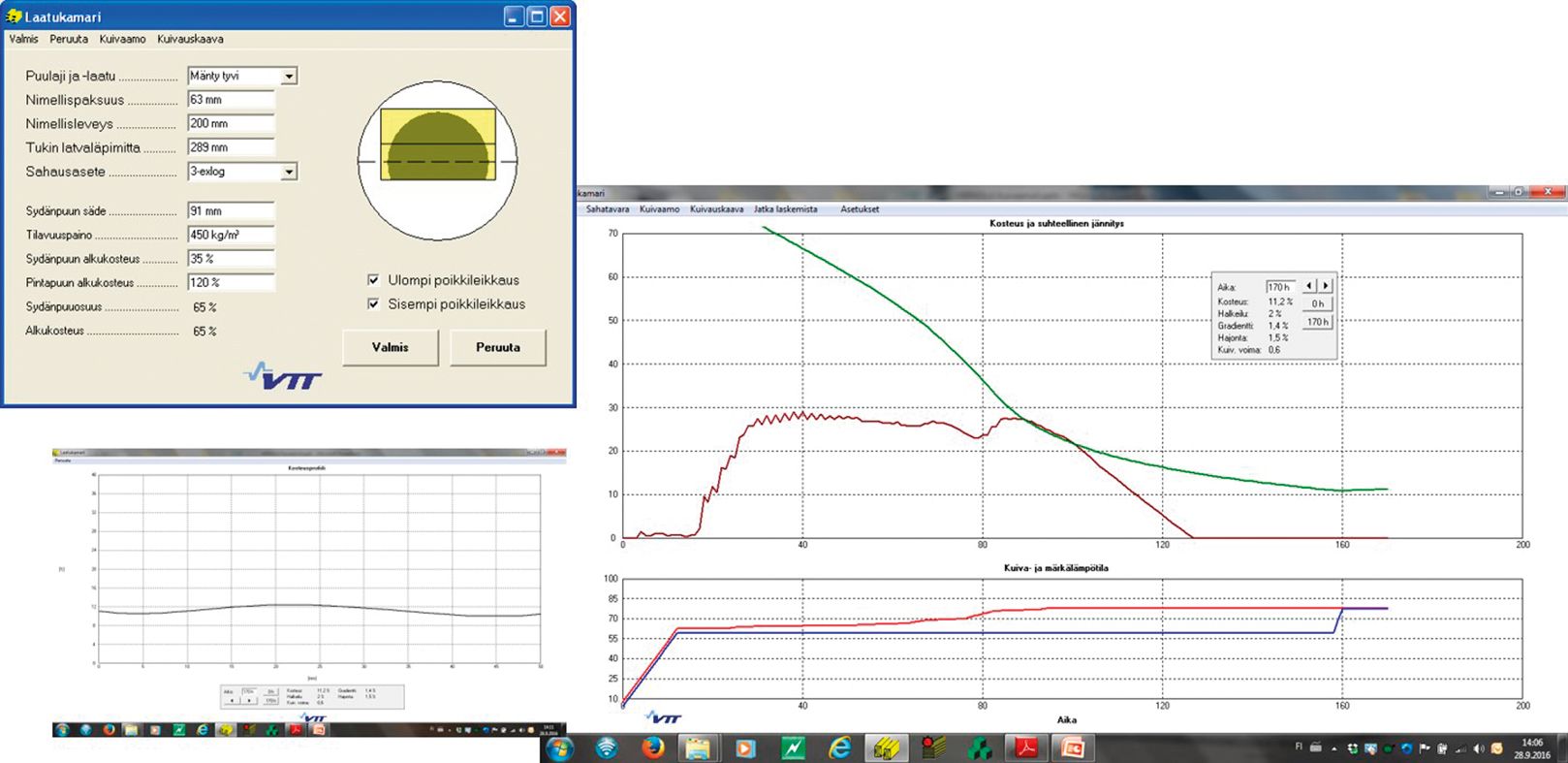

Simulation tools for creating drying schedules

Simulation models are computer-based programs that are used to create or optimise drying schedules. Simulators can be integrated into the kiln’s control systems or used as a separate unit.

The development of simulators in Finland started off as a cooperation between the sawmill industry and the VTT (Technical Research Centre of Finland). This cooperation lead to the release of the Laatukamari (“Quality kiln”) simulator.

In practice, the optimisation of drying schedules in simulators is based on experiential information and the physical properties of timber. The more advanced simulators allow you to better take into consideration the effects of air flow speed on drying. Simulators are useful when the initial data are correct, which means that users

Drying stages

Air circulation in the different stages of the chamber kiln drying process is described below:

The heating stage

In the heating stage, the purpose is to heat the drying batch from the outdoor temperature to the drying temperature where the actual drying process starts. In winter, this also means melting frozen water in the sapwood.

The heating time depends on the outdoor temperature, the size of the batch and heating and steaming power. Uncontrolled drying in the heating stage should be avoided.

The capillary stage

The capillary stage starts the actual drying of the freshly sawn timber. At this stage, sapwood still contains considerable amounts of free water that is loosely bound by capillary forces and moves easily.

At this point, the degree of drying is controlled by the heat that moves from the air into the timber to be dried. Drying is fast but the process requires heat and ventilation capacity.

If the batch mainly contains heartwood, the capillary stage will be shorter due to the fact that heartwood contains less free water than sapwood.

The transition stage

The transition stage is a stage where the capillary action between the wood’s pores stops and removing free water from the wood becomes harder.

The capillary rise of water towards the evaporation surface near the surface of the piece ends and the drying speed decreases dramatically when steam diffusion starts to affect the drying speed.

The diffusion stage

The diffusion stage. When free water has been removed from the wood, bound water still remains in the cell walls. This water must be vaporised and diffused towards the surface, which takes time.

As a result, the drying process is much slower than in the previous stage. The drying speed depends on the diffusion properties of the wood.

The stabilisation stage

Once the drying process is completed, the dried timber always has differences in moisture content both between different pieces and within one piece. The pieces also have internal tension. For this reason, the moisture content and tensions within the batch need to be stabilised by steaming or spraying.

The cooling stage

Timber bending can be prevented by using load presses. © Koskisen Oy

After the drying and stabilising stages, the batch should be cooled down. Generally, this is done by bringing the batch out and storing it under a shelter. However, fast cooling during winter means that the surface dries fast, which can cause checking. In these conditions, the batch can be cooled down inside the kiln while it is carefully monitored for overdrying or the batch can be cooled down by lowering the temperature via the drying automation system.

Energy consumption of drying and drying costs

The costs of drying timber mainly consist of electrical and heat energy costs, decreases in value caused by poor drying quality and capital costs related to the kiln. These explain 80–90% of total costs.

The remaining costs come from servicing and maintenance and staff as well as from the interest of the capital tied up in the timber.

Heat energy

In the drying process, heat energy is needed mainly for water evaporation and, to a lesser extent, to heat the timber and the water in it to the actual drying temperature.

Apart from what is consumed by ventilation, no technical solutions or usage of the kiln will make much difference in the consumption of heat energy.

The most significant cost factor in drying heat consumption is the amount of water being vaporised from the timber. The two extremes are a thick piece of spruce that is dried from the initial moisture content of 60% to the final moisture content of 20% creating water evaporation of roughly 150kg/m3 and pine sapwood boards with nearly four times the evaporation need at 550kg/m3.

Due to these differences, the specific consumption of heat, which shows how much thermal energy is needed to remove one litre of water from timber [kJ/kg H2O], is the best way to describe kiln thermal economy.

The typical heat energy consumption rate is 200–400kWh per dried cubic meter of timber.

Electrical energy

Electrical energy is consumed by the kiln’s air circulation fans. The electrical energy fed into these fans is fully converted into heat energy. This heat energy covers the heat dissipation of the actual kiln building.

Electricity consumption is highly dependent on the speed of air flow. This is why chamber kilns especially are equipped with frequency converters that allow the fan speeds to be brought down when the highest speeds are no longer needed at the final stages of the drying process.

Reaching a final moisture content of 18% of shipping-dry timber requires on average 30kWh/m3 of electricity which costs around EUR 1/m3 if the tariff is EUR 0.03/kWh.

If the kiln’s air circulation fans are not equipped with frequency converters, electricity consumption is directly proportional to the drying time. This means that if timber is dried to “carpenter-dry” quality, i.e. to a final moisture content of 8%, the electricity consumption doubles in comparison to the shipping-dry quality.

The savings that can be gained with a frequency converter is on average 30% of total consumption.