© Heinolan Sahakoneet Oy

There are two main stick-stacking line types: the lug line and the mat line. The line depicted is a lug line. The differences between the two lines are outlined below.

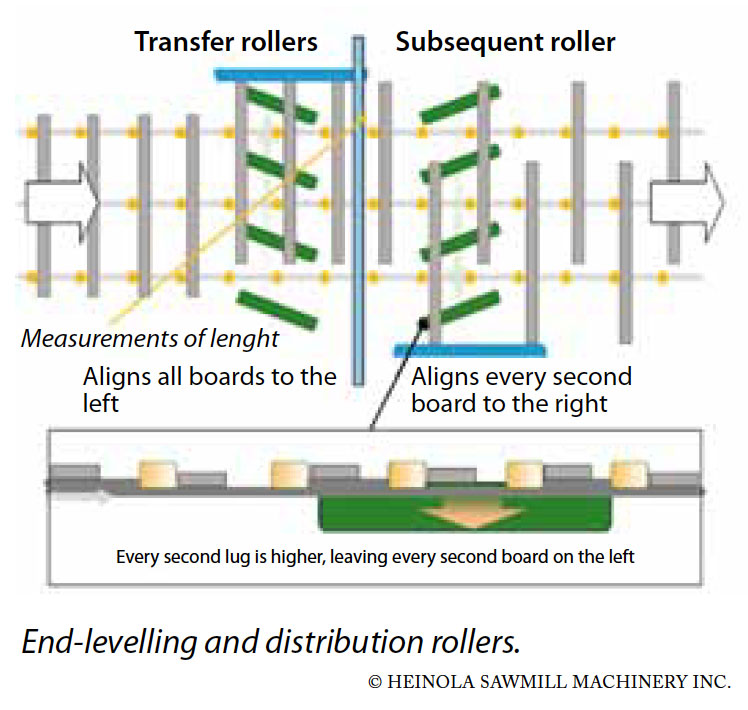

- In the lug line, a distributor table downstream of the loader transports the separated boards between lugs, aligns them and feeds them into the collecting conveyor. The first aligning rollers sort all the boards into a line. The subsequent rollers align the boards in every other lug so that their butt ends are in a line.

- In the mat line, boards are not transported between lugs but rather travel side-by-side on a chain conveyor. The boards are then aligned to the right and divided so that every other board is pushed out. After this, transfer rollers take the boards that were pushed out to the left-hand side and align them. The boards on the right-hand side are pressed down to keep them in place so that they do not move with the transfer rollers.

Both methods produce a package of even length with room for drying air to circulate. Length measuring photocells are located above the conveyor. These are used to measure the boards, with the data then recorded in the package record.

Principle of stick-stacking line

Pictures above and below present the principles of stick-stacking.

- The collecting conveyor collects boards transported from the distributor table into a tight layer using conveyors of different speeds. A record is kept on the distribution table transfers (board/empty); this is used to move the collector conveyor forward if there is a board in the last lug of the distributor conveyor. With continuous feed, the collector conveyor runs continuously. If there are no boards in the lugs, the collector conveyor stops.

- The boards fed in by the distributor conveyor lugs are counted, and when the last board in a layer enters the conveyor, the layer forks are activated after a time lag depending on the conveyor speed.

- The rotating layer forks lift the layer up and transfer it onto the package lift; the arms then move downwards and return to their original position leaving the layer of boards in the package lift. The layer forks are moved back and forth by an electric servo motor, which enables easy manoeuvring and high stacking speeds.

- A stick frame is lowered onto the top of the layer and holds the sticks in position. Information on the sticks used is included with the stick-stacking instructions. The frame also has the task of keeping the layer in place while the layer forks pull out. The stick frame is moved up and down by a servo cylinder and typically has stick cassettes every 40–80cm which can be filled manually or by machine. The outermost sticks are placed 1–2cm from the package end for heartwood and 5–10cm from the package end for boards. This is done to avoid the load drying too quickly, which may cause end checks.

- The sticker-stacker sequence is repeated until the set number of boards/layers has been stacked into the package lift. When the package is complete, the package lift lowers it for transfer onto the exit conveyor.

- From the exit conveyor, the package is transferred on beams or a cart on tracks into a buffer storage location or directly into a kiln. Packages can also be transferred by a forklift truck. The load information is sent from the stick-stacker automatic control system to the production control system that maintains the buffer storage location.

Stick-stacking line dimensions and capacity

The speed of the layer forks is around 12–15 layers per minute. For example, it will transfer 15 125-millimetre boards in one layer. If the speed is 12rpm, the stick-stacker table speed will be 180 lugs/min.

One lug can carry two 100mm boards, and one layer is formed of 20 of these boards. This means that the table speed will be 120 lugs/min (240 pcs/min) if the speed of the layer forks is 12 layers per minute. The time between batches is around one minute.

Size of batches: thickness, width and length of sticks

The size of a kiln load depends on the size of the kiln (chamber or progressive). In general, the length of a load is 6,000–6,500mm, the width is 1,600–2,100mm and the height is 2,300–6,000mm. Usually, the width of the load is at least a third of its height.

The sticks between layers are usually sawn spruce that is 25–50mm in length, 25-32mm in width and whose length matches the width of the load.

The method of stacking varies depending on the dimensions involved and determines how many sticks are placed between layers. The first layers of the load can be strengthened so that initially, for example, 11 sticks are placed between the first few layers and then only 9 sticks between the rest of the layers.

Alternatively, sticks can be stacked between every other layer, so you have two layers together with no sticks, then sticks in between the next two layers, then two more layers with no sticks, and so on. Both methods protect thinner boards against bending or breaking at the lower layers of the package.

Thicker heartwood pieces can also be used to prevent the sticks from breaking so that the piece at the edge of the layer always has the same end levelled. This way, the stick will not have to bear the heavy end on its own but the lower layer will give it some additional support. In the lug conveyor, this means that one lug is left empty if the layer has an odd number of boards.

The finished packages are kept in buffer storage before drying.