The objective of automation is to control the machinery and equipment as well as the items so that they operate and travel through the process as planned. The purpose of automation is to have the items travel through the process as fast as possible and without interruptions so that the yield value gained from the items is as high as possible.

Sawmill process automation includes discrete automation, automation process for by-products, exploiting the data in manufacturing execution system and safety automation.

Items include logs, cants, planks, boards and sticks. The automation process also includes a separate automation process for managing bark, sawdust and chips.

Various scanners are integrated into the process in order to provide dimension and quality data on the items that are then used to control the process. The data acquired during the process are transferred to the manufacturing execution system.

Sawmill units

The significance of automation systems for the sawmill industry is great. The desire to continuously try to develop more efficient production while reducing costs places high demands on automation systems.

A typical sawmill consists of the following units:

- log sorting

- feeding

- sawline

- by-product processing

- dimension

- stick-stacking line

- drying kilns

- aligning and packaging.

These processes tend to always be in the same order, it could be said that the previous process is a customer of the next process both at the unit and item levels.

Automation structure

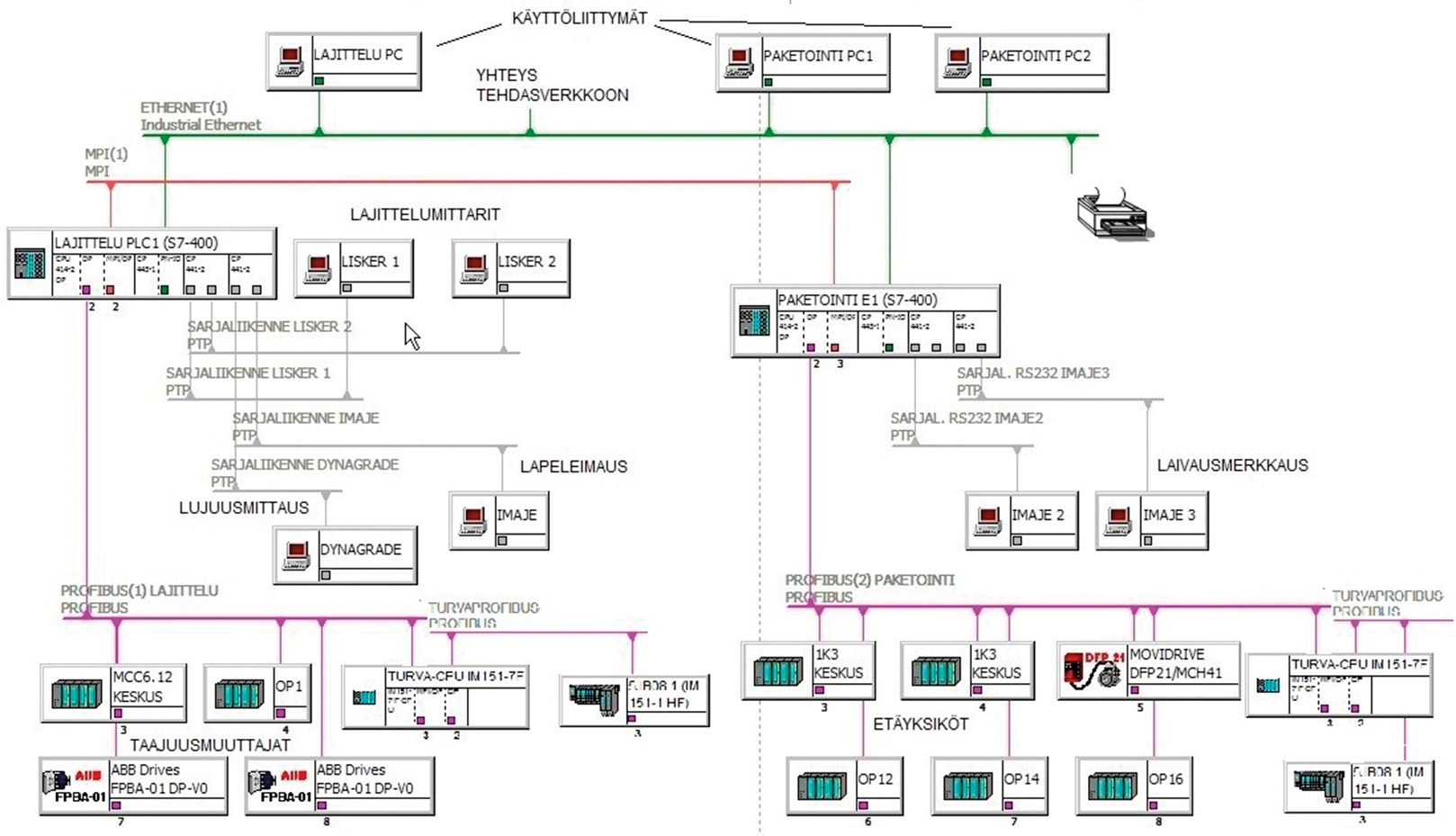

The automation structure in sawmills is complex and consists of equipment and software from many suppliers. Each section of the sawmill can be seen as a clear process like this.

© OT-Control Oy

When planning the automation system, it is advisable to apply the standard guidelines created for the particular saw”mill and use the components and equipment defined in the guidelines.

PLC and PC

A line automation system consists of different sensors and scanners that collect data during the process. These are connected to PLC (Programmable Logic Controller) or PC computers that run the automation software that controls the process. The centre of the automation system is the PLC or a separate PC device which runs the actual automation software. Automation software can be produced by different programming methods and languages that are partly dependent on the selected technology.

The automation systems gather data and transfer it to valves, frequency converters and motors. They also feed processed information back into the scanners. When information travels in both directions, processes are well controlled.

Automation systems also include safety functions for the equipment and lines. The automation systems receive manufacturing execution data from higher systems and they also send data gathered from the process to the higher systems.

Gathering data

The field components used for gathering data include:

- Limit switches

- Inductive sensors

- Photocells

- Ultrasound sensors

- Position sensors

- Light curtains

- Safety features

Process control information is received from scanners that contain various sensors and computers themselves. Typical scanners used at sawmills include:

- 2D and 3D log scanners

- X-ray log scanners

- Cant scanners

- Board edging optimisation scanners

- Timber quality scanner

- Stress grading scanner

- Moisture meter

- Length scanners

- Thickness scanners

- Widths scanners

- Weight meter

- Grain orientation scanners, so-called frontend scanners

- Process control smart scanners

Controls

Automation systems typically control machinery indirectly through controls and directly through contactors and relays.

Direct control is becoming rarer as machinery must be able to keep up with the process at alternating speeds and settings.

Indirect controls consist of different types of computers that process information. With the different versions of these controls, it is possible to use special applications. One of the most common such applications is an electrical synchronous drive system using frequency converters. In this solution, two separate machines are kept synchronised electronically without any mechanical connections.

Typical indirect controls include:

- Frequency converters

- Electric servo controllers

- Hydraulic proportional and servo controllers

- Compressed air proportional controllers

© OT-Control Oy

Typical directly controlled equipment includes:

- on/off type hydraulic valves

- on/off type compressed air valves

- Direct drive motor, for example in simple refuse conveyors

The automation system consists of I/O (input/output) modules or data communications cards that receive digital and analogue signals from the field equipment. The information from scanners and controls is transferred via various industrial buses and networks in the same way as information travels to higher systems.

Buses and networks used for data transfer include:

- Serial communication

- Profibus

- Profinet

- Ethernet

- Modbus

There are situations where decentralised systems must be used and processed data must be filtered to make software loop time sufficient. Typically, software loop time must be under 10 milliseconds to allow all the data to be read and movements to be carried out at the correct times. The most common automation system within the sawmill industry is based on

Siemens technology. Its products, distribution and support network are known worldwide, and the availability of components and spare parts is good.

Maintenance

The automation system requires servicing just like mechanical components. Automation components can become faulty as a result of an external reason or due to expiring.

It is advisable to organise the maintenance of the automation software with the automation supplier that has the resources and ability to sort out any problems as they arise.

A remote connection for communication and making alterations allows the process to be monitored or altered remotely.