The main purpose of scanning cants is to optimize the side boards. In principle cant open surfaces can also be graded to determine optimal sawing pattern in secondary breakdown based on for example knot size, quality and count.

The 3D-model of scanned cant can also be used to optimize positioning before secondary reducer, where the main idea is to prevent concave side excessive wane either in the side boards or center pieces.

Side board optimization

Side board optimization decides board width and position. Skewing is often applied, meaning that board is produced in diagonal way compared to cant center line to maximize volume.

Skewing can increase side board yield by 1–2% in primary breakdown, when log sweep in up or down. Secondary breakdown yield increase is typically much less with skewing, normally round 0.5%.

Compared to fixed profiling, optimizing of side boards typically increases the side board volume over 10%. It also produces better quality by symmetric wane.

It’s easier to scan and optimize the side boards on a profiling sawing line compared to edger line, due to much lower production speeds. The scanned object also moves on a profiling sawing line in an ideal manner; centered and with constant speed.

© Lisker Oy

Edger line optimization

Many sawing lines have a separate edger line for side boards or several of them. This was more or less a standard before the profiling sawing lines became dominant.

The unedged side boards coming to edger line can either be volume optimized or value optimized by having a grading of boards as well. Grading takes into account wane, knots, pitch pockets, bark pockets and other grade affecting factors. Volume optimization can also emphasize certain widths and lengths.

Grading edger optimizers are mainly used with pine. In case of spruce it’s typical to have only volume optimization.

Scanning can be transverse before centering of the unedged board or longitudinal after the centering.

Longitudinal scanning can have 1-3 scanning heads depending on the distance to edger saw. With shorter distances, more scanner heads are needed.

Optimization time is normally under 100 ms, already including data communication to PLC system.

Edger line speeds are typically 2-4 times bigger compared to sawing lines. This means that correct timing of edger control is crucial for edger line yield.

© Lisker Oy

Sawn timber thickness control

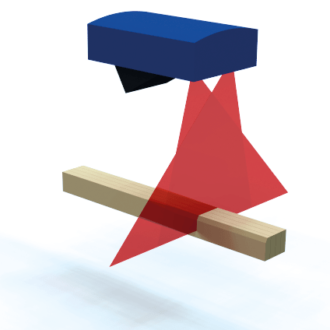

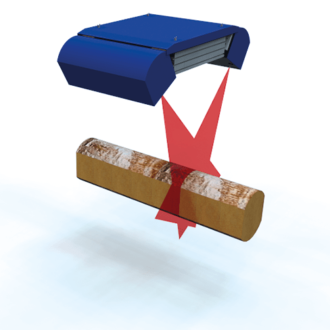

Both center piece and side board thicknesses can be monitored real-time with camera systems above the sawing line. Scanning principle is either triangular measurement with lasers and matrix cameras or line scan cameras with specific optics.

The benefit of on-line control of thicknesses is the rapid response time to undersized sawn timber or to too big standard deviation, often caused by sawing blade fatigue. Operator can avoid producing defective products thus saving valuable raw material and money. On the other hand, systems can save by not producing too much over thickness. Overall the tolerances of sawn timber thicknesses can be better controlled.

The pictures below show the principles of 1D and 2D laser-scanner systems, which control sawn timber thicknesses on-line.