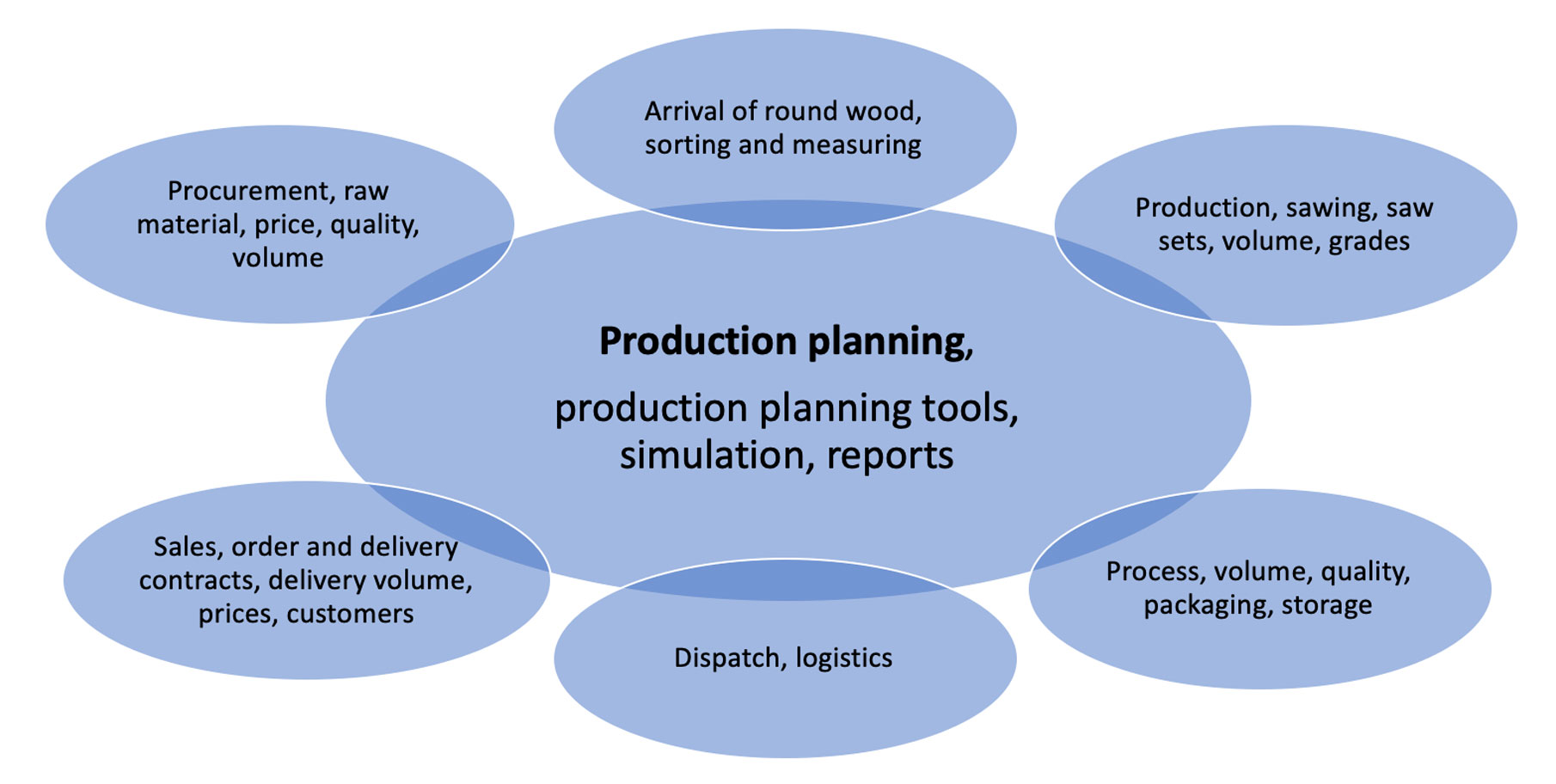

Production planners are responsible for the sawing plans, either for one or several sawmills. Usually, in companies with several sawmills, the long-term planning is conducted centrally and the short-term planning is done at the mills.

The way production and sales planning are conducted varies between different companies, depending on their strategies, resources and whether the raw material procurement is in own hands or done by supply partners.

Link from stump to customer

The production planner is an important link between forest department, production and sales

The work is steered by, among other things:

- Anticipation of log inflow, based on delivery data, log reserves and log stock

- Steering of log yard

- Cutting plans for the production

- Value, yield and profitability calculation to support the sales

- Known deliveries

- Time tables for deliveries and its follow up

Production planner also gives feedback about the accuracy about log procurement and sales predictions.

Time frames of planning

The efficiency of production planning can be measured by production efficiency, stock turnover or operational profitability.

Production planning is usually divided into cycles that help plan, for example, quarterly production and sales.

Production planning can be divided in three parts:

- long-term planning

- mid-term planning

- short-term planning

Long-term planning

In long-term planning, the time span is usually a year.

Annual planning is a part of the overall strategic planning, where previous years’ actual data is being used for instance with the log size inflow, quality yields and such.

The goal of annual planning is to match together the requirements from the sales department with the projected incoming log supply.

In order to get full benefit from the planning one needs to have relatively accurate customer information of the existing customers and also of the potential ones.

The expected log supply – first obviously converted into sawn goods – is then divided between markets, even down to customer and product level.

Mid-term planning

Mid-term planning is based on monthly periods or, in case of a mill cutting both Redwood and Whitewood, suitable time periods for each one of them. There are also mills, which make the plans on a quarterly basis.

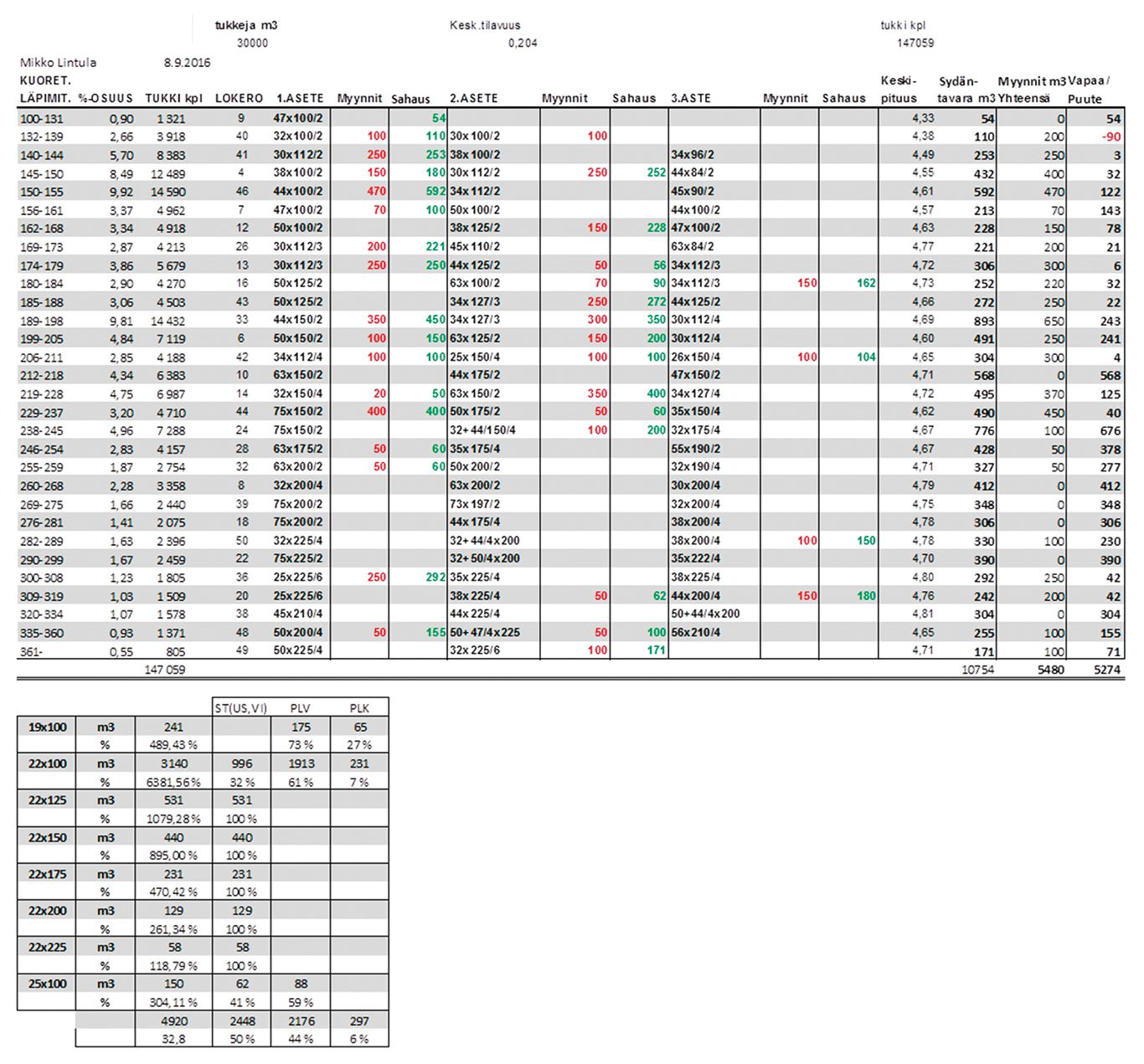

At this point, one knows already the available log volume and its top diameter and often also the length distribution. The plan takes into account the sales contracts, stocks and the wishes of the sales people.

The production plans are based on matching the sales of centre cut goods. However, the planner must also take into account the demand and stocks for sideboards in various thicknesses and widths. Production planning must also be prepared to make alterations to the original plans, if the agreed sales volumes are not going to be met, or if the improvement of stock turnover requires changes to the saw sets.

If there are sales with non-standard dimensions or special lengths, the production planner may either make a specific order with the Forest Department, or alternatively required logs are picked out of the incoming log inflow. At the log sorter these logs must be kept separate from the normal logs.

© Westas Oy

Short-term planning

Short-term planning is in practice a very detailed process for following week’s production.

Factors affecting this are for instance the graded log stock, ready dates for the contracts, the flow in the production chain and the overall situation within the cutting period.

Weekly plans create a solid production program for the upcoming week or weeks.