The camera-based applications are used widely in sawmill industry. Typically camera-based systems are used in grading of green and dry timber.

Both systems are based on machine vision. Automatic grading systems have replaced manual sorting.

Green grading

In green grading just after the sawline, the boards are graded according to dimensions and often also based on visual grade.

Grading / edger

The unedged boards from the sawline can be edged with automatic edger before the sorting line and then combined with the main stream of the boards.

Laser-based dimension measurements are normally used in the edgers. With camera-based grading system even the quality of the board can be analysed. The scanner can be either lengthwise or transversal depending on the layout of the edger mechanics.

In the edger the measurement on one side is enough if the board is being transported wane up. In case the board cannot be turned wane up the measurement should be two-sided. The cleaning of bottom side needs then to be arranged regularly because of moisture, pitch and dirt.

Grading / sorting plant

In the green grading many defects in the boards can be detected more accurately than in the dry grading. If the quality sorting can be done already in the green grading the grading in the dry sorter becomes easier. The grading system in the drying line can focus more on defects caused by the drying process.

Optimal green grading allows an optimized drying process. The best grades can be separated and dried with good results according to customer requirements.

Off-spec boards should be removed or trimmed in the process as early as possible. It is not worthwhile to transport and dry off-spec boards.

Measurements in the grading line

In the green grading process, the basic dimensions like thickness, width and length are measured. The deviation to nominal values needs to checked. The inaccuracies caused by the sawline should be corrected as soon as possible.

The measurements are performed lengthwise or transversally in the grading lines when the boards are moving along the line.

- When measured lengthwise the space needed for measurement is quite small, but a long and fast conveyor is needed.

- On the transversal line, the line speed can be over 200 boards /minute and still the measurement can be done with good accuracy.

The dimensions of the board can be measured by laser-based measuring devices or by cameras.

Camera-based machine vision systems can measure all the key features of the board. Thus the board needs to be analysed on all four faces and sometimes even at the end face of the board.

The following properties can be measured with the machine vision system:

- board dimensions

- wane

- splits, shakes

- knots, holes

- colour differences like blue stain and decay

- pitch pockets

- insect defects

- pith location

- warp, bow, crook

Grading / end of the board

In the end of the board the following features can be analysed:

- distance of the annual rings

- ratio of spring/summerwood

- cracks

- decay, blue stain

© FinScan Oy

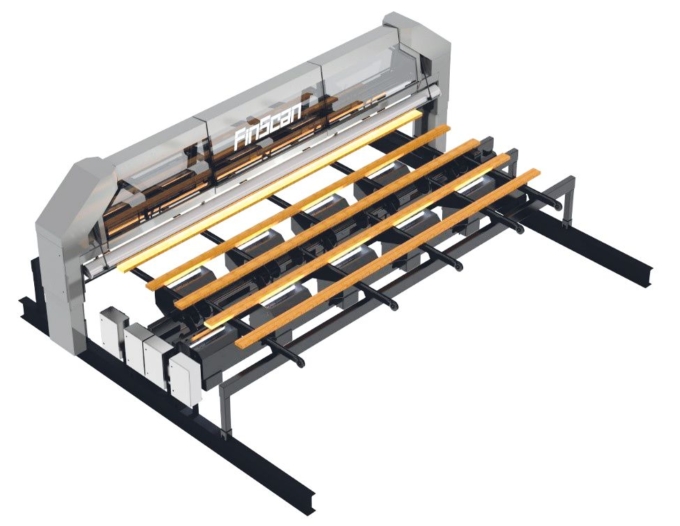

Case: BoardMasterNOVA-N

BoardMasterNOVA-N quality grading system has six cameras on the top side and ten cameras (in two rows) on the bottom side. Board is transferred from one conveyor to another one allowing complete analysis of the board. The edges are analysed twice so that all inclined and deformation defects can be correctly defined.

© FinScan Oy

Dry sawn timber sorting principles

The final sorting of dry sawn timber is carried out in the grading line before packaging and transportation to end customers. The dry sorting of sawn goods follows the same principle than the green sorting.

The measurements of moisture in the dry grading

In the dry grading it is possible to measure also the moisture of the boards. The moisture measuring device can be part of the automatic grading system.

© FinScan Oy

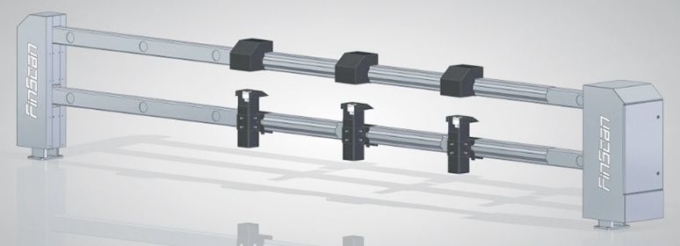

Component grading

Automatic machine vision system can also be used for remanufacturing purposes. The system can perform special grading e.g. for component production or for the finger-joint lines.

© FinScan Oy