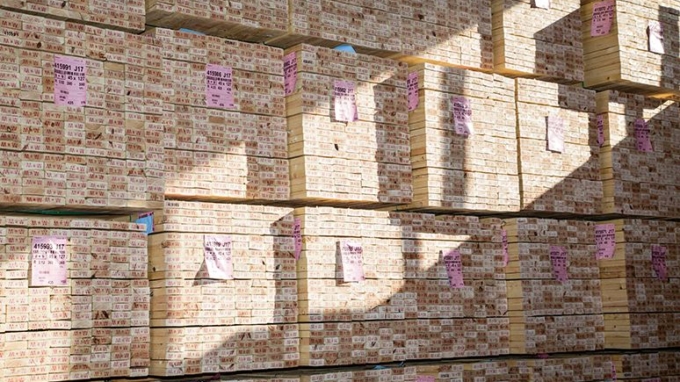

The timber packages that are ready from the packaging plant are finally transported to the storage area. This can be outdoor storage, a one side open storage shelter or a storage hall. Sometimes storage halls with overhead travelling cranes are in use.

Maintaining of a storage

Well-maintained storage protects the timber packages against moisture, dirt and mechanical damages and makes the inventory of the stock easy.

Principle of FiFo

Usually the principle of FIFO (first in first out) is followed at the mills, meaning that the oldest packages are delivered first. The aim is to keep the inventory rotation of sawmill as short as possible and not to commit working capital unnecessarily to the stock of finished products.

The transfer to the warehouse is often done with a forklift truck. The selection of the storage site depends on the quality of the sawn timber.

Higher grade goods are always stored in a shelter or a hall. Lower qualities and fresh sawn timber can be stored outside, sometimes protected against weather and dust by covering them with tarpaulins.

Group packages

In front of the packaging plant, the fork lift truck mostly combines the timber packages into groups of four packages with two packages side by side at the bottom and two on top of them. There are wooden spacers in between the packages to make the handling easier. The forklift truck takes the bigger group of four packages to the warehouses. The height of the pile of packages depends on how high the truck can lift and on the height of the shelter or the hall. The edge stacks are often lower for safety reasons.

When setting the wooden spacers between the packages, the operator must take extra care.

The spacers in the wrong place can easily cause the timber package to deform or even break pieces of sawn timber. In the storage hall with an overhead travelling crane, the forklift truck or the side loader move the packages on the access road to the hall. The overhead travelling crane moves the packages to the place of storage. In the hall with overhead travelling crane the piles can be much higher than in the shelter or the hall.

Bar code

The package label with a bar code makes it easy to read the package information with a bar code reader. It is therefore easy to register the storage location of each package during the inventory/stock.

Similarly, when a package is loaded on a means of transport, a package specific bill of lading may be printed at the same time. Simultaneously the packages are removed from the inventory list.

Shipping

When the shipment of timber packages to the customer starts, the loading instruction in the data base of the sawmill determines the quantity and order. The shipment from the sawmill takes place either by lorry or by train, sometimes by container.

- Sawn timber to be exported by sea transport is taken to the port according to the instructions given by the forwarder. There are also storage facilities in the port, where timber packages can wait for the ship to be loaded.

- Sawn timber can also be shipped in trailers which are loaded at the sawmill or in containers that can be loaded in the port or at the sawmill with special container loading equipment.

- With rail transportation there is a development towards so called whole train transport, where a certain minimum number of wagons is loaded at any one time.

© Metsä Group/Tomi Aho