Before the log reaches a sawing machine, a number of peripheral devices and functions are required. From the log sorting station, the logs are transferred into a buffer storage location until sawing of their particular log batch starts.

The logs are usually brought into the sawline feeder using a loader or similar machinery. The sawline feeder transfers the logs into an unscrambler, step loader or screw loader and then one by one on to a long lug conveyor.

Debarking is followed by sawline feeder. Stages are:

- Turning the logs

- Metal detection

- Buffer storage and feeder conveyors

- Log rotation and positioning

The logs are fed into the sawline through measuring and debarking. The conveyor line is also equipped with a metal detector. It may also be necessary to turn the run direction of logs as the top first to debarking and sawing. The layout of the sawlines determines lateral moves of logs, distribution methods and directional turning needs.

The logs are fed into the sawline through measuring and debarking. The conveyor line is also equipped with a metal detector. It may also be necessary to turn the run direction of logs as the top first to debarking and sawing. The layout of the sawlines determines lateral moves of logs, distribution methods and directional turning needs.

© Metsä Group/Tomi Aho

Log turner

A few exceptions apart, most modern sawlines aim to cut logs top end first as the log is then easier to align for the first working unit.

The lug conveyor:

- The lug conveyor often has a scanner that detects whether the log is travelling top or butt end first.

- Based on the data received from the scanner, the log is turned into the desired position in the next working stage.

- The turn is normally performed by a pusher underneath or a revolver turner above. After this is done, the log will have made a 90-degree turn.

- Since the pusher or revolver turner movements cannot be stopped in the middle of the turn, a small buffer storage location is located immediately after the turner in order to even out the infeed to the debarker, which is next in the line.

The chain conveyor and turning plate:

- In the chain conveyor version, only the logs to be turned make a 180-degree turn using a semi-circular chain conveyor, while the other logs continue directly forward on the lug conveyor.

- A similar 180-degree turn can be performed on a turning plate.

Metal detector

Debarking removes any impurities in the bark, such as stones and pieces of metal. A magnetic metal detector is usually located after the debarker to detect possible pieces of metal inside the log.

The metal detector allows for any logs that contain metal to be pushed off the line into a storage bin from where they will be transferred for further processing. Similar bins are used for over- or under-sized logs as these can often cause problems at later stages of the process.

Buffer storage and feeder conveyors

There is often a small buffer storage location between the debarker and sawline, the purpose of which is to even out any process interruptions that may occur in the debarker or sawline.

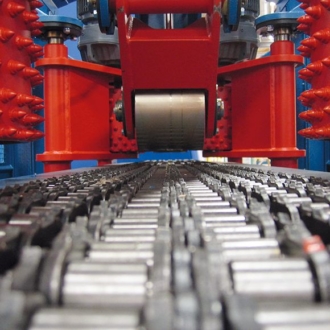

After the buffer storage location, the logs are again loaded on to a sawline feeder conveyor, thus ensuring the desired gap between logs.

In optimising sawlines, the start of the feeder conveyor is often divided into several parts in order to regulate the gaps between logs.

By increasing or decreasing the speed of the conveyors, you can adjust the gap between logs to match the optimised gap set by the log scanner, so that the movements necessary for the machinery at later stages of the sawline process can be performed.

Log rotation and positioning

At the end of the sawline feeder conveyor, there is a log scanner that scans the shape, curvature, ovality and length of each log.

Based on the scanning data and sawing pattern data set for the batch, the logs are rotated into the desired position by the log rotator so that the sawing pattern set for each log can be optimally performed at later stages of the process.

Log rotating and positioning equipment has become more advanced as feeding speeds at sawmills have increased. They have considerably improved feeding accuracy by being closely connected to the subsequent sawline machines.

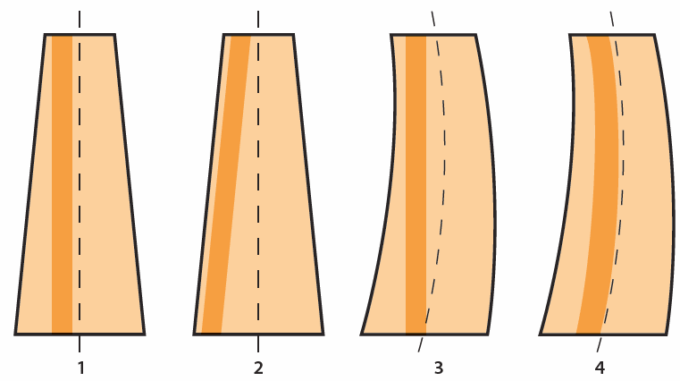

The sawing pattern can be chosen:

- to follow the log’s core

- the log’s surface (taper sawing),

- the log’s centre line or

- the log’s warp

The most common method is to follow the log’s core. In this method, the sawing pattern is straight, and the blades are only subject to the forces of normal cutting resistance.

Any lateral forces on blades are due to variations in the wood’s density.

© Tuomo Kauppinen / Antti Saikkonen

- Sawing line parallel to the longitudinal axis (straight log)

- Sawing line along the surface of logs, taper-sawing (straight log)

- Sawing line parallel to the longitudinal axis (curved log)

- Sawing line along the surface of logs, taper-sawing (curved log)

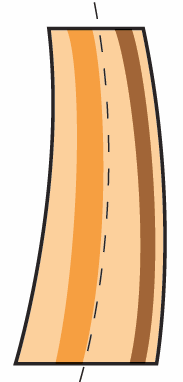

Logs can also be sawn so that the log’s warp, or longitudinal bending, is taken into consideration. This is called curve sawing.

This means that a log with a warp in one direction is turned before the first sawing stage so that the log curves in the desired direction. This way, the log’s centre line can be followed in a controlled manner.

Warping affects the yield obtained from a log. The entire centre cut area of the log can be removed.

© Tuomo Kauppinen / Antti Saikkonen

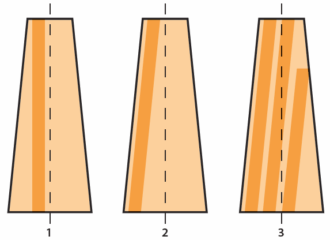

1. Sawing line along the center line of the log.

2 and 3. Sawing line along the surface of the log, taper-sawing.

A curved log, the difference between the curved saw and the taper-sawing. © Tuomo Kauppinen / Antti Saikkonen

Taper sawing performed using volume optimisation can recover thick timber from tapered logs more efficiently than sawing along the centre line. This may slightly affect the strength, and the technique is more complex, but the method is widely used is North American sawmills. In this method, the main product is a two-inch plank, and no side boards are cut.

- The difference between the traditional sawing method and the curve sawing method. ©Veisto Oy

Timber cut directly from a warped log is partly waned in the middle and at the ends. If the cut timber is square edged without curve sawing, the yield is reduced. The benefits of curve sawing depend on the log quality and length distribution at a particular sawmill.

In Central Europe, product lengths are usually shorter (3–4m) than in the Nordic countries (4–6m). As a result, Central European operators have paid less attention to the benefits of curve sawing.

Further processing must be taken into account when deciding on log positioning.

- Curve sawing must be performed so that curvature is on the face and not on the side.

- Curvature of the face can be worked to some extent during drying, but curvature of the side cannot.

- The log must be fed into the sawing machine with the warp facing in the right direction.

Rotators

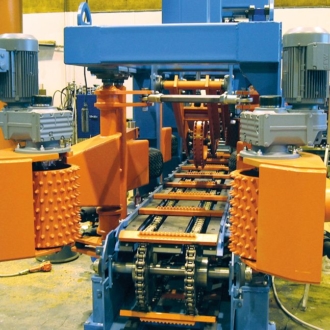

Due to higher feeding speeds, sawmills have moved away from positioning based on the visual monitoring of the operator and introduced more mechanical or computer-controlled feeder technologies. These rotator devices produce a more accurate and flawless log positioning for sawing, and there is no need to stop the log during the process

The log can be rotated:

- using either short spiked rolls with adjustable vertical angles,

- long spiked rolls that move up/down or

- rotor turners where the spiked rolls move along the rotating frame.

It is essential for successful rotation that the rotated log stays in the set position as it travels towards the first sawing unit. This is usually ensured by using a centering conveyor which has centering side rolls that keep the log in the set position.

In optimising sawlines, centring conveyors can be used to adjust the log’s centre line in relation to the sawline centre line with the aim of maximising yield