The sawing process consists of individual main machines, as well as adjacent conveyors and downstream conveyors. Together, these make up the actual sawline, which aims to turn each log into an optimal number of saleable sawn goods and by-products, in line with the market situation.

Description of sawing methods

There are multiple different sawing methods existing but one common tradition that is used in Nordic sawmill industry.

The purpose of the sawing process is to use sawing and edging to produce as much high quality timber that meets the requirements of the buyer as possible.

Nordic tradition

Sawing in the Nordic tradition:

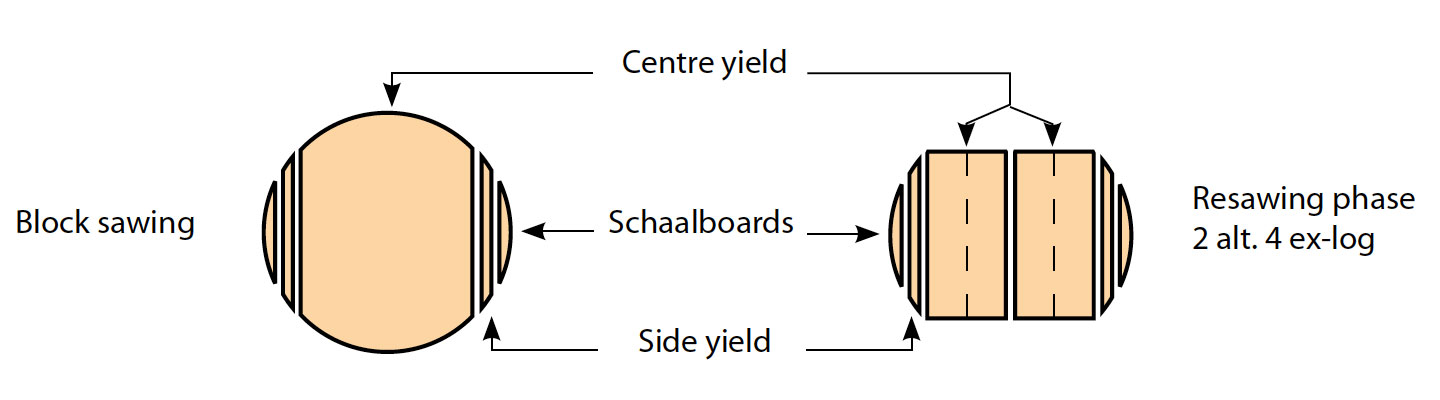

- First, the cant is cut out.

- The cant is halved from the middle in the resawing stage.

- Other cuts divide the log into the centre yield and side yield.

- The centre yield consists of two or more sawn pieces that may be of the same thickness or different.

- Exceptions to this sawing method (e.g. heart-free) are called special sawing methods and their use is always agreed separately between the sawmill and customer.

- The most common sawing method used in the Nordic countries is to first cut out the cant which is then divided into the centre yield and side boards during the second phase of sawing. Source: Pohjoismainen sahatavara -kirja (2016), © Antti Saikkonen

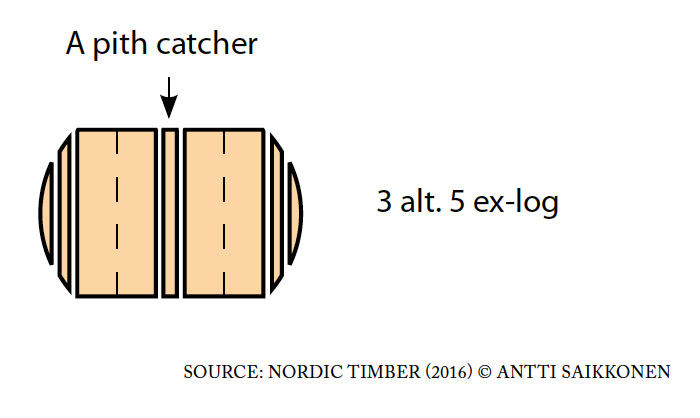

Heart-free sawing

Sawn timber that contains no heartwood is produced by cutting out the middle of the cant as one piece. This way, the pith and its possible defects are removed from the centre yield, which is the main product.

Summary of the sawing methods

The purpose of the sawing process is to use sawing and edging to produce as much high quality timber that meets the requirements of the buyer as possible. Tähän päämäärään pyritään erilaisilla laiteyhdistelmillä ja tekniikoilla. This is done using different machinery combinations and techniques

The different sawing patterns give a different yield from the same raw material. Moreover, the amount of work required to produce the final product and the further processing methods varies greatly.

In Finland, the dimensions and moisture content of processed timber are defined in the RT manuals published by Rakennustieto (an organisation providing building information). The manuals show the permitted deviations in accordance with Standard EN 336.

1. Cant sawing: removing side boards, turning the can’t 90° and resawing

2. Through-and-through sawing

3. Quarter sawing

4. Grade sawing

5. Trapeze edging

6. Asymmetrical sawing

7. Component sawing