Turnover and costs are an essential part of profitable business.

Turnover

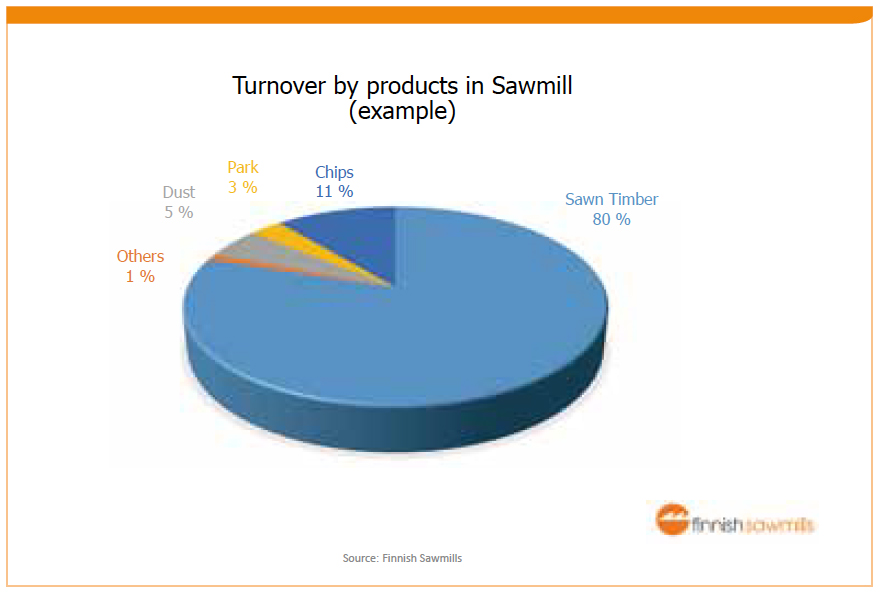

The sawmill industry’s turnover comes from the sale of sawn timber, wood chips, sawdust and bark. Sawn timber’s share of the turnover is around 80 percent and the by products are about 20 percent. However, the sales of pulpwood that is procured in the log procurement process is not included in this calculation.

Often, in sawmill companies, the log procurement and potential processing of sawn timber is done by separate companies. For example, these could be the sawmill’s parent or sister companies. Thus, the distribution of turnover varies substantially between different companies depending on how the business is structured.

The cost structure

The costs vary from sawmill to sawmill depending on what kind of strategy the sawmill is implementing and what kind of technology the mill is operating with.

The differences that appear in the cost structure are substantial. In this review, the focus is on the cost structure of an example sawmill.

Example sawmill

- The largest cost of a sawmill is the cost of the raw material. The raw material share of the total costs is just over half (the example sawmill’s share is 52 percent).

- The second largest cost factor is made up of the harvesting costs, the transfer of the logs to the roadside and transportation to the sawmill (8% + 5% = 13%). The example sawmill’s costs related to the raw material is 65 percent of the total costs.

- The freight cost of sawn timber is the third largest cost at around 9 percent. The freight cost’s share of the total cost fluctuates, as the terms of a sale varies depending on the markets, customers and the sales channels. Provided that the sawn timber is sold with the terms as delivered to the customer, the freight is shown on the sale as a cost item. However, the freight cost of the sawn timber will be charged from the buyer as a higher sales price. In other extreme case, the customer will collect their order from the mill, at their own expense. In this case the freight will not show on the sawmill’s costs. Almost all sawmills sell their products in numerous different delivery terms. Respectively the raw material costs for sawmills focusing on sawing small, short and lower grade logs might seemingly look lower, but face higher production costs and lower sales opportunities.

- The impact that wood harvesting, as well as the transportation of both the raw material and sawn timber (8% + 5% + 9% = 22%) has on a sawmill, in terms of energy and transport policy (taxation, maintenance, etc) is very significant to the sawmill’s competitiveness on the global market.

- The personnel costs vary between 5 and 10 per cent against all costs. Variation can be explained by, among other things, the level of sawmilling technology and automation employed.

- Some mills have outsourced some or all of the maintenance in order to reduce costs. Experiences of this have varied somewhat. At the example sawmill the maintenance is not outsourced and its share of the costs is about 4 per cent.

- Sawmilling is relatively speaking a capitalintensive business. However, the working capital’s importance – on top of the money tied in the machinery – is big in log stocks and sawn goods stocks and accounts receivable.

- A major part of Finnish sawmills’ machinery was renewed in the 1990s and early 2000s, and now most of it has been fully depreciated in the accounts. On the other hand, there are new investment needs for the processes. Capital costs are affected by the interest rates, which with the example sawmill are low at the time of the study.

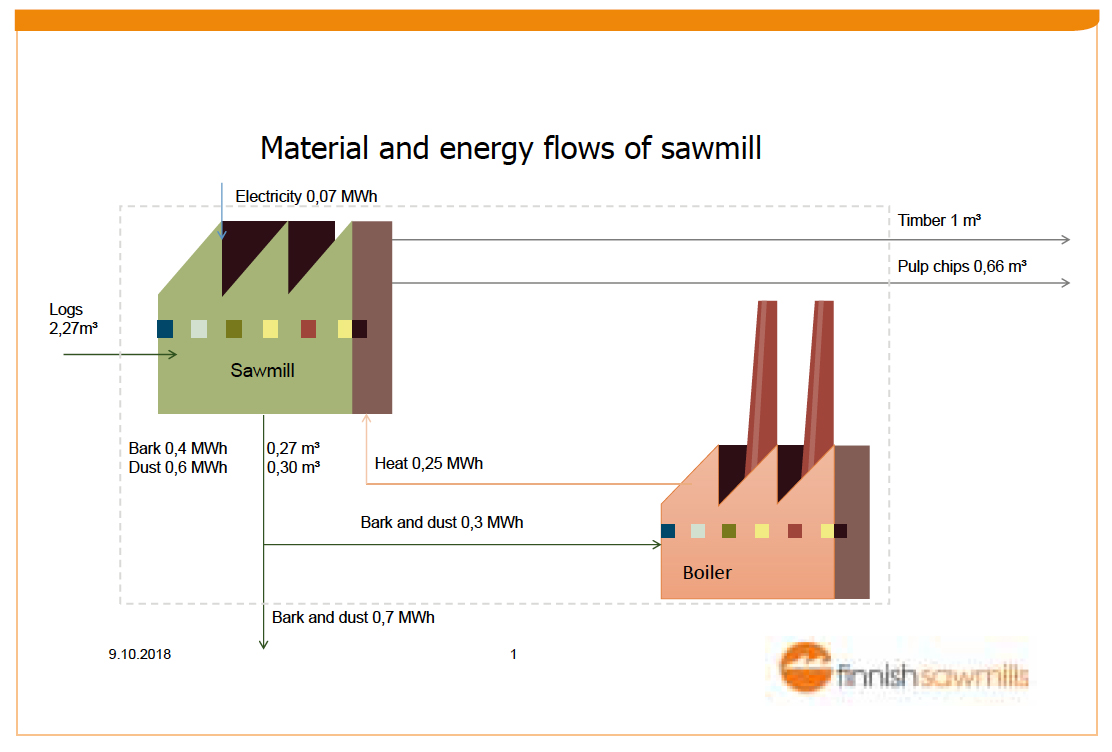

In the picture, the cost structure of sawmilling has been split into various cost groups by various stages of the process.

For instance, the wages at the example sawmills are 9 percent, but if one also takes into account the costs outside the actual sawmilling production such as felling, transport and haulage, the share of wages rises to 23 percent. The share of fuels rises then to 11 percent, although at the mill the fuel consumption for forklifts falls under the heading “others”.