The Finnish sawmill industry has initially consisted of sawmill companies, many of which have grown into multi-sector forest industry companies in the last millennium.

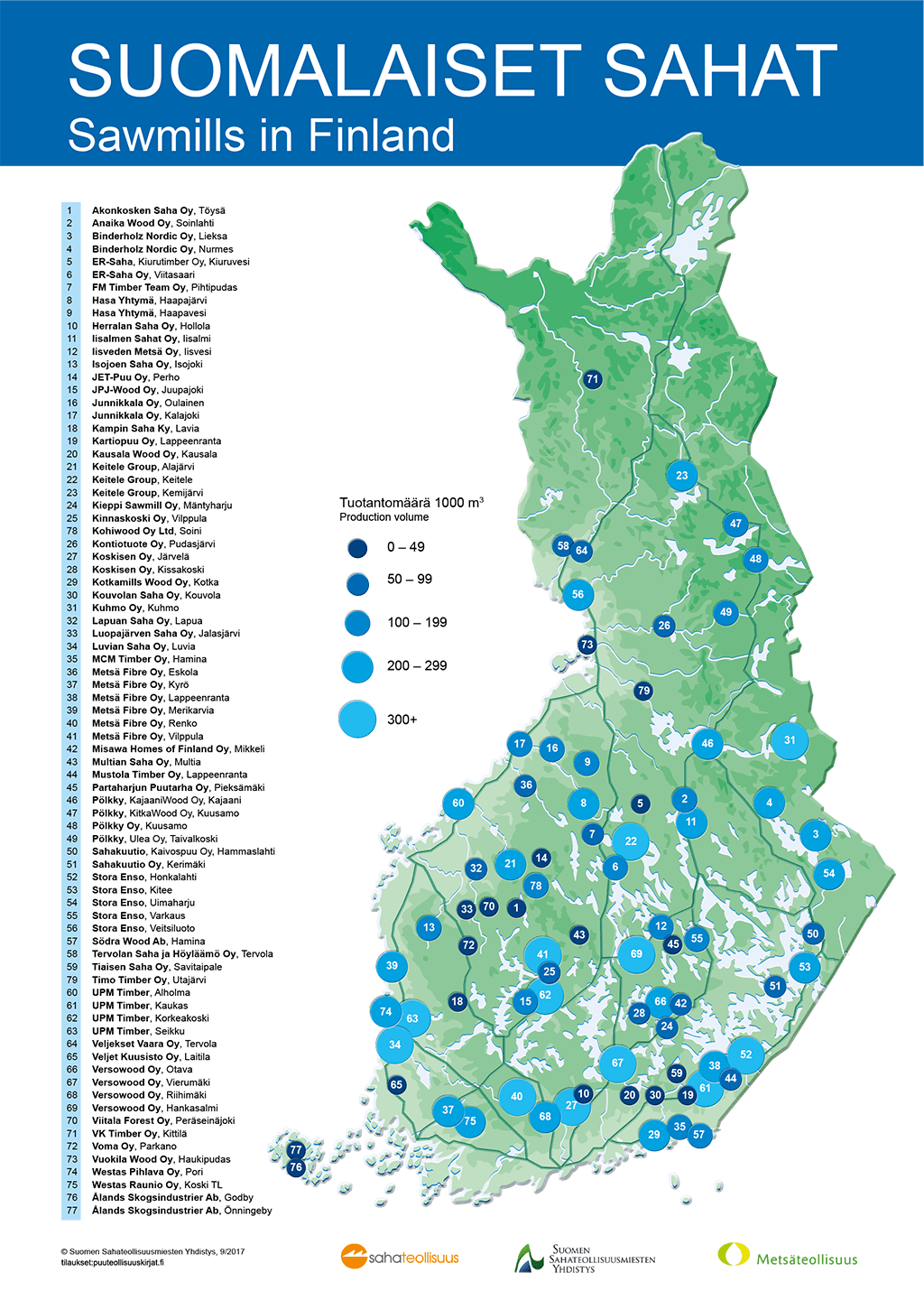

Independent sawmill companies have grown in size since the 1950s. Today those companies account for more than half of sawn timber production. In addition, there are numerous small sawmills operating in our country.

Small sawmills

The smallest sawmills are entrepreneur owned, fixed or movable circular or band saw units usually employing 1-2 people. Production volumes vary from some hundreds of cubic meters to a few thousand cubic meters.

Many small sawmills saw local forest owners’ logs on a contract basis, with the goods remaining with the forest owner for his own use.

Some sawmills buy the logs and sell the products locally. A few sawmills produce small volumes of special goods to the export markets, too. On an annual basis, the combined small sawmill production is estimated to be around 0.5 million m3, which equals to less than five per cent of Finland’s overall production.

Sawmilling in the biggest integrated forest companies

Bigger forest product groups see sawmilling as a part of their integrated business model. Sawmilling has, on top of the actual sawmilling function, a significant role in supporting the sourcing of pulp wood. Furthermore, their sawmills supply large quantities of chips to the group pulp mills.

Typically, large forestry groups have 4–6 rather sizable sawmills, with capacities ranging from 200,000 m3 to 600,000 m3. The status of sawmills varies slightly between the organisations. Sawmills can be run as a separate daughter company, or they can be a part of a larger profit centre, such aspulp industry or forest department.

The sawmill business itself is typically very straight forward, based on fewer and bigger customers. Bigger groups have almost completely withdrawn from the further processing business. Sawmillls operate globally. The share of integrated sawmills is around 40 percent of the overall production.

Independent sawmills

Independent sawmilling businesses are family companies, to whom sawmilling is the core business. The annual production varies from about 10,000 m³ to over 1.3 million m³.

Log procurement is based either on own forest department, or various degrees of cooperation with forestry associations, forest sourcing companies or integrated companies.