Change factors

According to research looking at the future, overall it is expected that technological developments will continue to accelerate and have a stronger impact on everyday life and consumer habits.

Digitalization

Digitalisation is strongly advancing in all areas of life and is a factor that will influence the future of many industries, and perhaps, most importantly in communications.

In Finland, the use of paper has steadily declined and the chemical forest industry has experienced operational upheaval with a shift from paper production to cardboard and pulp.

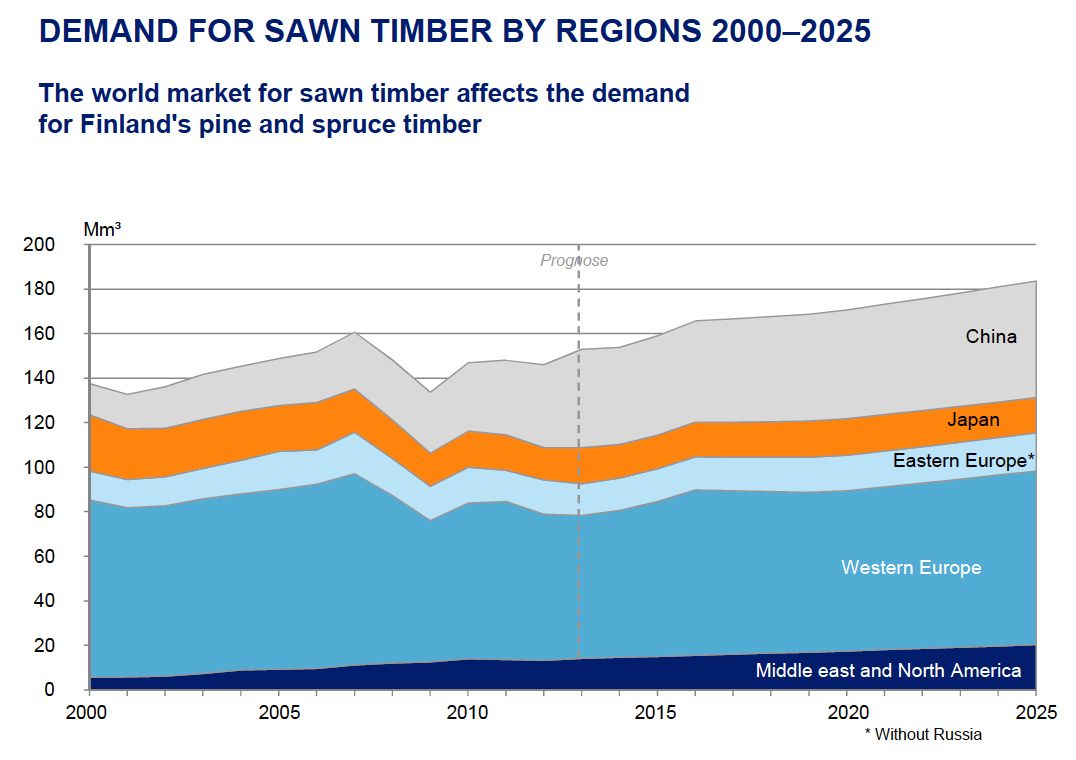

This development has not affected the consumer habits of trading timber products in the same way. There are no great structural changes expected for the use of timber. Finnish timber is used for many different applications globally, including for the building, construction, carpentry and joinery industries as well as in the furniture industry.

There are several substitute materials for timber that can be used for these end uses. In addition to traditional metals and plastics, there are products based on bio composites that will be introduced to the market.

The popularity for genuine wood materials is rising.

Timber is a renewable, natural resource which is a recyclable, ecological, warm and breathable material. The overall consumption of timber is expected to grow in the future.

Demand for sawn timber until 2025. © Pöyry. Source: TEM report: https://tem.fi/documents/1410877/2772829/P%C3%B6yry_Suomen+mets%C3%A4teollisuus+2015-2035.pdf/ac9395f8-8aea-4180-9642-c917e8c23ab2

The crucial availability of raw material

The availability of the raw material for the sawmills is rising.

The growth of forests in Finland has risen consistently and the annual growth has already exceeded the 100 million cubic meters milestone.

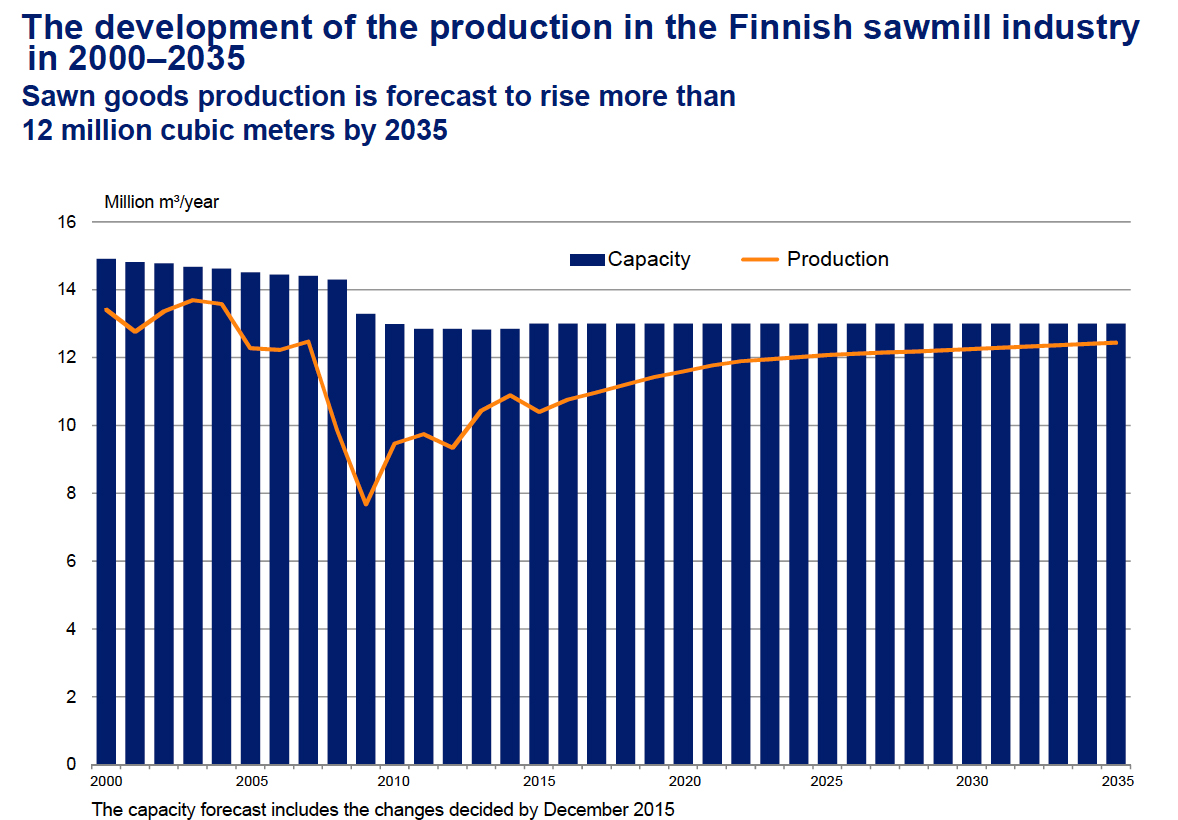

The development of the sawmill industry in Finland by the year 2035.

© Pöyry. Source: TEM report: https://tem.fi/documents/1410877/2772829/P%C3%B6yry_Suomen+mets%C3%A4teollisuus+2015-2035.pdf/ac9395f8-8aea-4180-9642-c917e8c23ab2

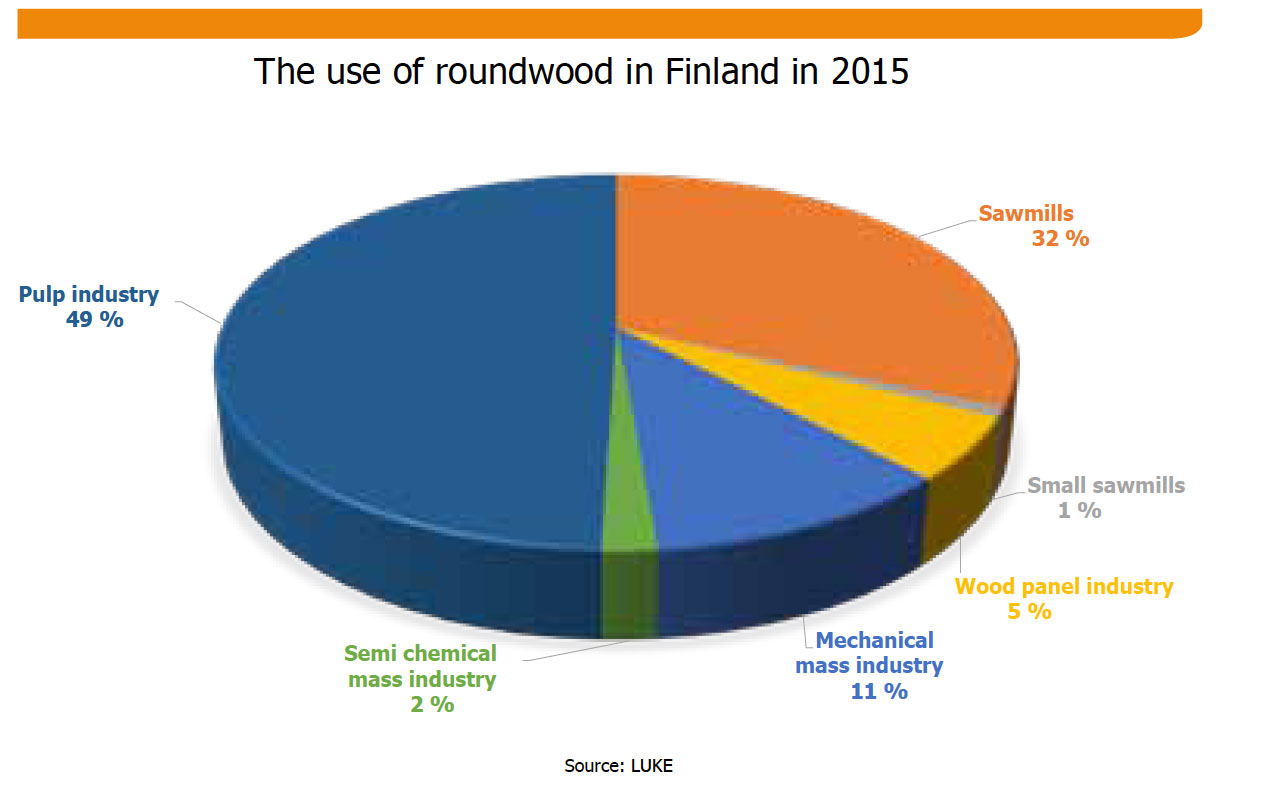

The sawmilling industry’s importance is central to timber trading.

The main contribution for forest owners logging revenues comes from the sale of logs eligible for sawing.

The increase of timber trading comes from ensuring sawmills’ high capacity utilisation and also enable additional capacity to be developed. The availability of logs is a challenge.

Developing the competitiveness

When assessing the future of the sawmill industry, one perspective is developing the sawmills’ competitiveness. The key cost element in production is the raw material. It represents, depending on the market situation, between 65-80 percent of a sawmills’ turnover.

Other important cost elements for sawmills include wages, transportation costs, electricity, operating costs and capital expenditure. None of these costs bring a competitive advantage in relation to competitors from different countries.

Sawmilling businesses create large nett sales, about two billion euros, but the sawmills’ profit margins are thinner. The export share of a sawmills trade is usually around 60-70 percent. Published results of sawmills have indicated that their average profitability has not been good.