Bark

Key concepts related to bark as described in Puutieteen perusteet (Basics of wood technology)(2003) by Matti Kärkkäinen include:

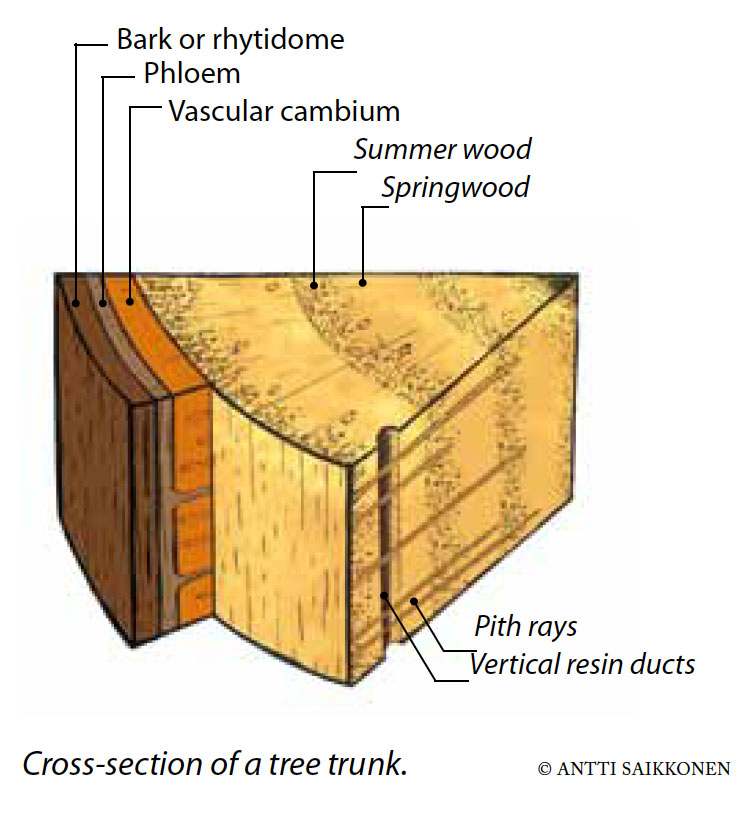

- Vascular cambium is a layer of tissue where the tree’s secondary growth takes place. The vascular cambium produces xylem on the inside and phloem on the outside.

- Phloem is the living tissue that transports organic compounds from the leaves to other parts of the plant. Phloem = inner layer of bark.

- Cork cambium is another layer of tissue capable of cellular division located outside the phloem and that creates cork on the outside. It acts as the divider between the inner and outer bark.

According to Kärkkäinen, bark includes all the tissue outside the vascular cambium layer. When defined in this way, bark can be structurally and physiologically divided into the inner bark, i.e. phloem, and outer bark. The inner bark means the tissue between the vascular cambium and the periderm (= cork cambium) that has formed last.

The outer bark means any layer of tissue outside the cork cambium. The outer bark, and especially the thick part of the outer bark, is often called rhytidome. The inner bark, or phloem, is normally a living tissue. The cork on the outer bark is dead.

The volume of bark

The volume of bark is defined either by its thickness or its volume or mass in proportion to the trunk or part of the log.

In timber procurement within the sawmill industry, the volume of bark in proportion to the log and the mass of bark in proportion to the chips are important factors.

The factors that affect the growth of bark include

- tree’s species

- age

- size

- the shape of the trunk

- the quality of top

- location in the forest

- growing environment

- georaphical location

The thickness of the bark increases as the tree grows while the volume of the bark in proportion to the total volume of timber decreases. Pentti Hakkila states in the book Metsävarat ja kuituraaka-aineet (Forest resources and pulp raw materials) that the bark on a fast-growing tree will be thinner than on a slow-growing tree.

The proportion of bark varies at different heights of the trunk. From the stem upwards, bark initially gets dramatically thinner and the bark percentage decreases. The rate of the change depends on the species. The change is particularly dramatic in pines and silver birches that grow a thick stem bark. At a certain height, the thickness of the bark becomes stable after which the proportion of bark increases again towards the top in all species.

Notice that, among logs from southern Finland, pine has a higher bark percentage (12.2%) than spruce (10.1%). In northern Finland, the situation is the opposite: pine has an average bark percentage of 12.0 and spruce 13.2.

Measuring

Within the Finnish sawmill industry, the proportion of bark of the volume of the tree trunk is not normally measured because trunks are bought with the bark still on. The mill measurement that defines the log’s price is carried out on barked trunks by an optic log scanner integrated into the grading line.

Because logs at Finnish sawmills are usually graded before debarking and the debarker is situated around the infeed unit, the log grade is defined using a calculated bark percentage based on regional statistics. The formulas, regional divisions and conversion factors are defined by the Natural Resources Institute Finland.

In many Central European countries such as Germany and Austria, the sawmill industry does not pay the seller for the bark at all. As a result, log volume measurements in these countries are conducted on debarked logs or whole trunks. As the logs have been debarked before they are measured at the mill, there is no longer any reason to estimate the proportion of bark.

This undoubtedly improves the accuracy of the logs’ diameter/volume sorting and also increases the yield from sawn logs. On the other hand, debarked logs are lowered to the ground before sawing, which inevitably increases blade maintenance costs.

The amount of chips is determined in dry weight

The proportion of bark in chips sold to the pulp industry should be as low as possible. The pulp industry determines the price of chips according to their quality. The proportion of bark is one of the quality criteria.

Depending on the intended use, the chips sold to the pulp industry are allowed to contain no more than 1.0% bark. If the figure is higher, the price will decrease as the amount of bark increases. On the other hand, plants may pay extra to the supplier if the proportion of bark is below 0.5%, for example.

The proportion of bark in chips sold to the pulp industry is determined in dry weight percentage instead of volume percentage. This way the different densities of bark and xylem, which can distort the bark percentage based on volume, will not be a problem.

This is especially true with pine that has stem bark that is considerably lighter than the rest of the bark and the xylem. In pulp production in Finland and the other Nordic countries, the bark percentage of chips is determined in accordance with Standard SCAN-CM 42:06.

Factors affecting debarking

The purpose of debarking is to break the vascular cambium layer between the bark and xylem and to remove the bark from the xylem.

- Debarking is done by applying adequate force on the vascular cambium layer so that the tension created breaks the bark and xylem as well as the internal bond between the two.

- Enough energy is applied onto the xylem so that it removes the bark from the xylem.

- Debarking is successful when it comes so close to the vascular cambium layer that it fully removes the vascular cambium from the surface xylem.

The internal bond strength between the bark and xylem varies significantly between different species and depends on the ambient conditions. The bond between the xylem and the inner layer of bark (phloem) is at its weakest when the tree grows the fastest in May and June. The bond is stronger when the tree is not growing.

Affects of drying

If the timber dries, the internal bond strength between the bark and xylem becomes stronger. The most significant factor to cause this is the growth of bonds between fibres in the vascular cambium layer. The cells of the vascular cambium do not lignify and are elastic. When moisture is removed from this layer, the bonding between fibres becomes stronger.

Moreover, the fact that the bark shrinks more than the xylem as it dries is likely to affect the increase of the internal bond strength between the bark and xylem. The adhesive effect from the vascular cambium layer’s extractives during drying may increase the internal bond strength.

Affects of temperature

The internal bond strength between the bark and xylem increases as the temperature decreases. This is why the bark on a frozen trunk is very tight. It is likely that this is caused by the strength of the vascular cambium cells increasing when they freeze.

The internal bond strength varies significantly between different species. Out of the commonly used species within the Finnish sawmill industry, the pine is more easily debarked when frozen than the spruce. The birch is even harder to debark when frozen than the spruce. Debarking becomes significantly harder in all species when the temperature of the bark drops below -15°C.

Affects of bark’s toughness

The bark’s toughness is also a factor because the forces created by the debarker are conveyed into the vascular cambium layer through the bark. For example, the bark on the spruce is tougher than the internal bond between the bark and xylem in its vascular cambium layer. As a result, the bark comes off in chucks.

However, the cork-like bark of the pine is weaker and so its bark disintegrates into small pieces during debarking. Even though the toughness of the bark is not significantly changed when frozen, the bark often crumbles into small pieces when a frozen trunk is debarked. This is simply caused by the increase in the internal bond strength between the bark and xylem as the timber freezes.